Page 38 of 73

Posted: 17 Sep 2016, 00:03

by lot_lizard

Techno Trousers wrote: It looks like you even got some charring on that test piece. Burn, baby, burn!

The first pass was gorgoeus (razor sharp). The next two passes were a deflected mess, and caused the excessive rounding. To clean up char, I would just likely throw the batch in a mesh net and run through the washer.

When we get down to 1/16, it will be a nice sharp edge on both sides

Posted: 18 Sep 2016, 11:25

by POTV

I have just found this thread a few days ago. The project looks very promising.

I have a few questions...

Will they only be made in the us?

What is the expected price?

Will there be enough for all DT-members?

(And what if the potential buyers supply their own F-switches?)

Posted: 18 Sep 2016, 14:12

by lot_lizard

POTV wrote: Will they only be made in the us?

They will be made in the US (aside from the PCB/controller), but we will send across the pond as sea freight to a Euro proxy to disperse and save on international shipping

What is the expected price?

We will be sub $150 for either the Full-size and SSK "kits", minus the salvaged switches. I'll know exact numbers once the final designs are hardened... we are close. This is being run as a non-profit buy. Any surplus we take in will reduce end shipping costs, or will be refunded

Will there be enough for all DT-members?

The only limited commodity are the salvaged switches. There should be enough for 50-100 boards in the end (I have news from Cindy I'll post very soon... It's goodness), with preference being given to contributors in the project, followed by club members, then followers of this thread, and finally the general DT populous.

(And what if the potential buyers supply their own F-switches?)

The hope is many are able to supply their own switches. We will be able to produce as many "kits minus switches" as we like. We will run the group buy in the coming weeks for approximately a month (at least until the switches are accounted for). Based on prior polling, half of everyone interested would be able to supply their own switches, so expect 100-200 "kits" being produced

Comments above in

blue

Posted: 18 Sep 2016, 14:42

by Hypersphere

@lot_lizard: Thanks for the encouraging update! Question for further clarification: If we supply our own switches, what will we need? I am assuming that a "switch" would be a barrel, spring, and flipper from an IBM Model F keyboard, such as an IBM XT keyboard. Is this correct?

Posted: 18 Sep 2016, 15:13

by lot_lizard

Hypersphere wrote: If we supply our own switches, what will we need? I am assuming that a "switch" would be a barrel, spring, and flipper from an IBM Model F keyboard, such as an IBM XT keyboard. Is this correct?

Exactly. A "switch" would be the flipper (spring and attached paddle) and the barrel. So if you have those, the "kit" will have the rest of the inner assembly. Our goal with Phase 1 is still to let you turn an existing Model M into an F by replacing everything except the case and keycaps.

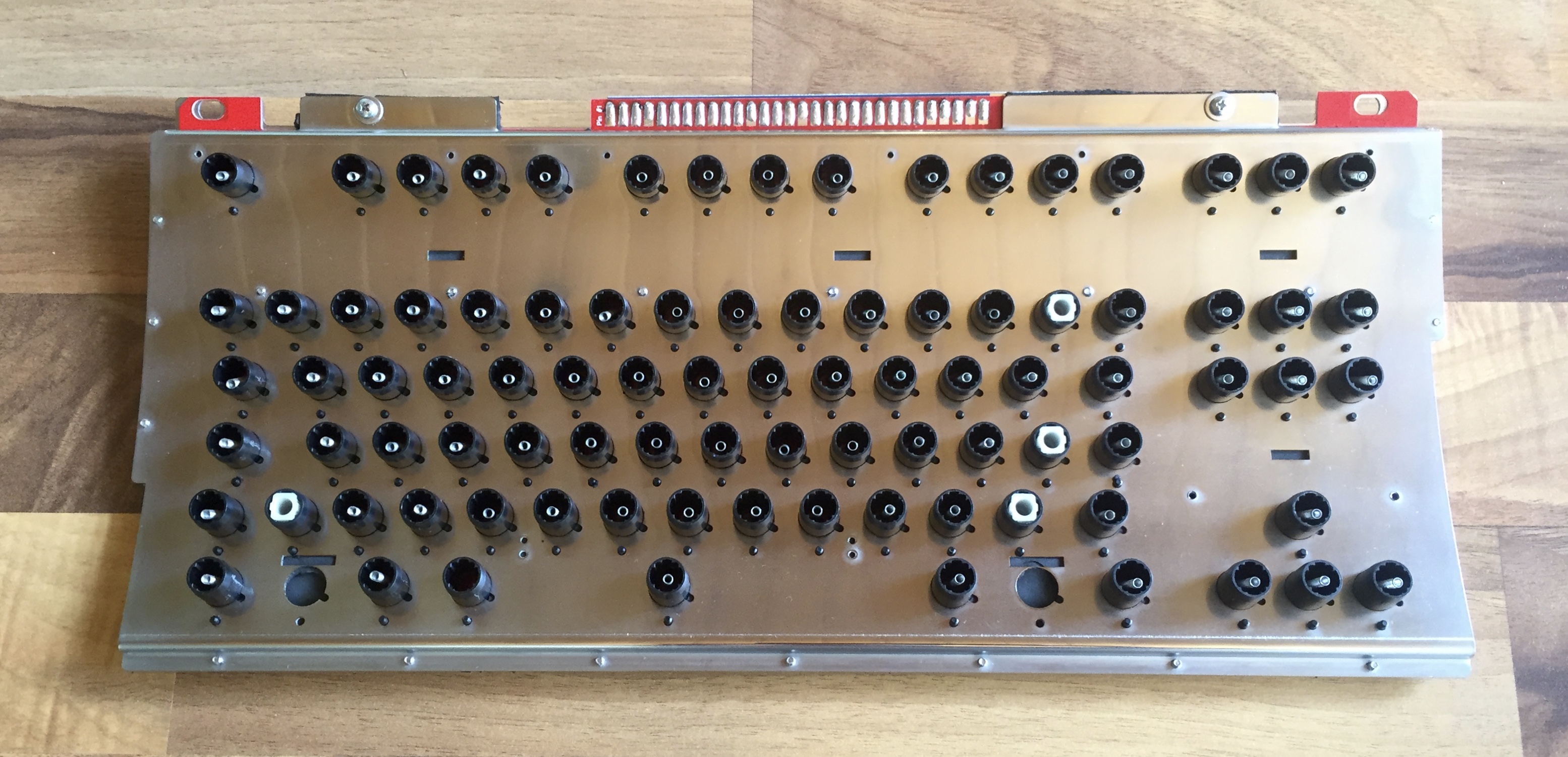

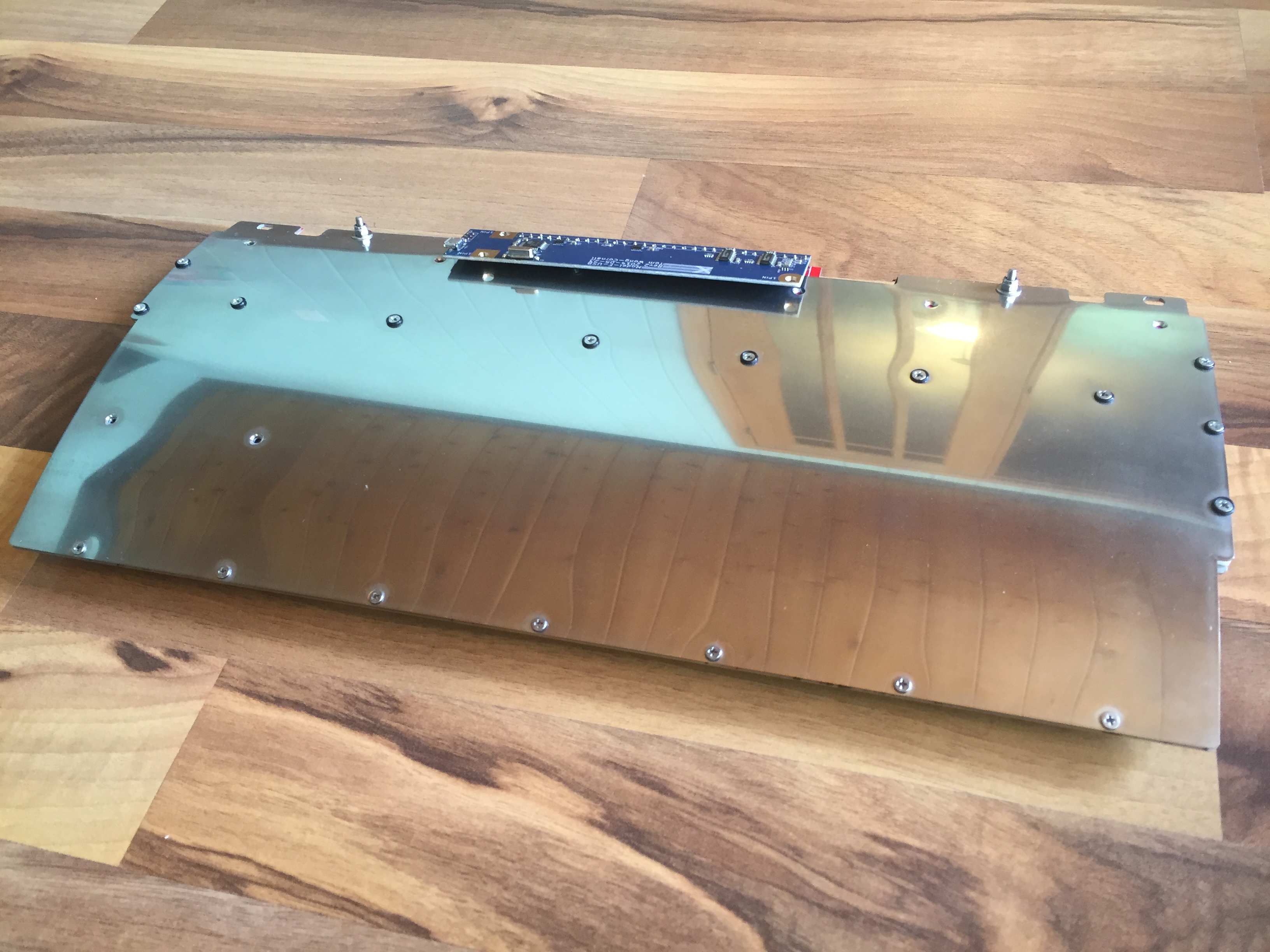

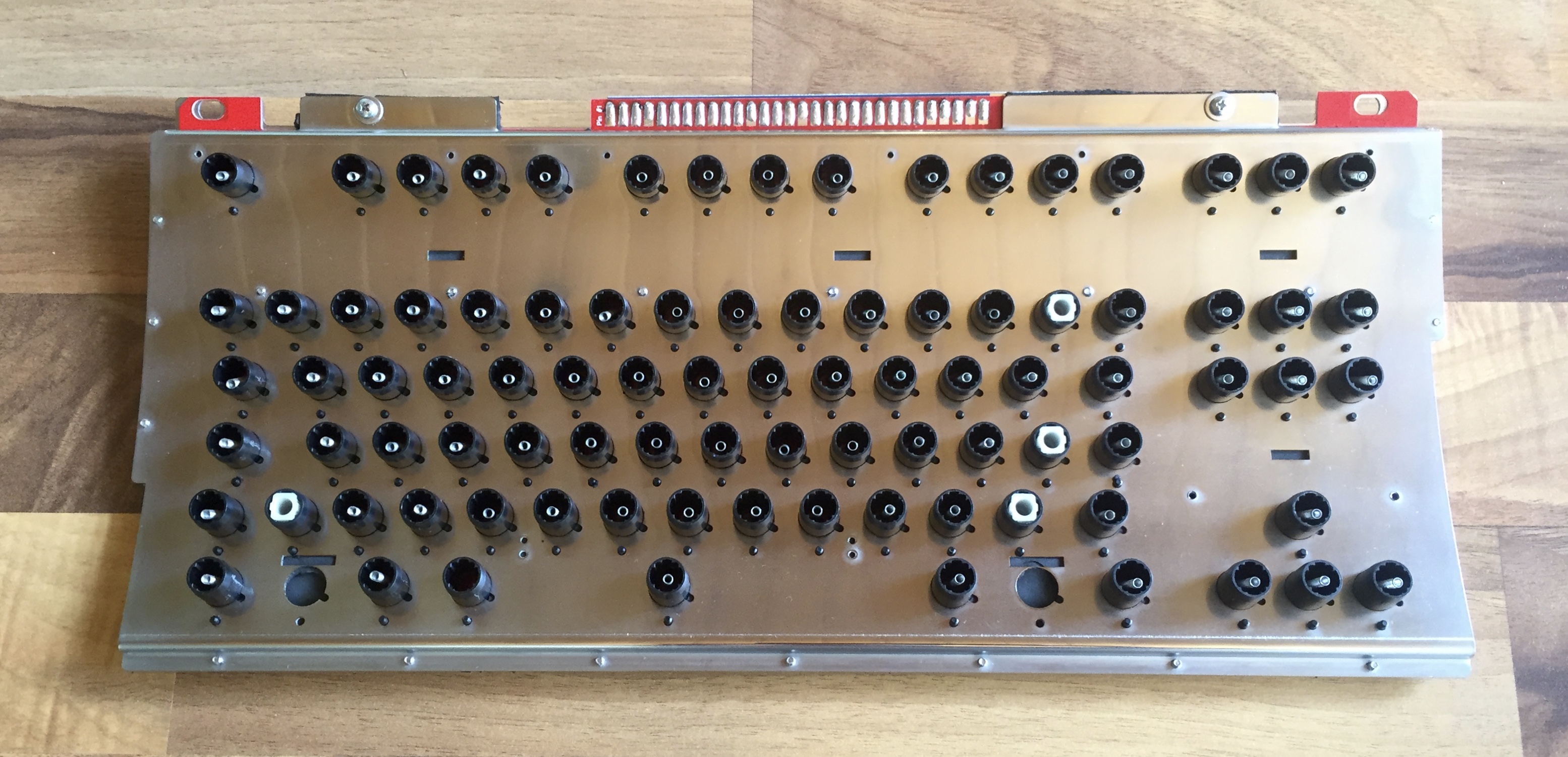

So basically the final version of everything you see in the following make up a complete "kit with switches". Like the switches, all of these parts will be offered "ala-carte". Cables are not shown, but would be available as well. Lots of color and connection options along the way.

Posted: 18 Sep 2016, 15:40

by POTV

@lot_lizard: Thanks for the update. It's a fantastic quest towards the best keyboard, I can think of - the SSK with F switches.

I would be able to provide switches for my own order, if there´s a shortage (F-122 board).

Re: (Model MF) Remodeling the Model M

Posted: 18 Sep 2016, 16:00

by Techno Trousers

Do you have an SSK case? As it stands now you may need one, depending on the final outcome of Phosphorglow's resin molding experiments. There is also a plan for metal cases to be made in a later phase, but the new curved plates won't be made again after this first group buy..

I'm planning to buy an extra SSK inner assembly to keep on hand and complete that build with phase 2 components.

Posted: 18 Sep 2016, 16:09

by POTV

Yes, I have 3 SSK's from 1987. Love them

Posted: 18 Sep 2016, 16:12

by POTV

And I'm probably also interested in 2 inner assemblys the same way as you...

Posted: 18 Sep 2016, 16:27

by regack

lot_lizard wrote:

So basically the final version of everything you see in the following make up a complete "kit with switches". Like the switches, all of these parts will be offered "ala-carte". Cables are not shown, but would be available as well. Lots of color and connection options along the way.

:drool: Where's the drooling smiley? Hmm...

I currently have 79 barrels (and 78 flippers), a few shy of the SSK - So when you say 'à la carte' would I just be able to pick up 10 more (barrels+flippers) to get to 84 w/a few spares? I could also start searching for a dead F... I kind of don't want to take apart the one functional one I have - even if I don't ever use it

Posted: 18 Sep 2016, 16:44

by lot_lizard

regack wrote: So when you say 'à la carte' would I just be able to pick up 10 more (barrels+flippers) to get to 84 w/a few spares?

Exactly right. Every part (there are many) will be available as individual quantities (spare top plate in a different color... whatever). The "kit" is just to make the order process easy. We will also be placing orders to Unicomp on anyone's behalf to save you some shipping there if interested if you need spares of theirs for anything (more intriguing to the international folks).

As far as individual quantities of things, all of these parts have to be hand counted anyway (so a kit vs. one offs makes no difference)

Posted: 18 Sep 2016, 19:39

by UnFocused

I just discovered this thread a couple of days ago and... WOW!

I have a full sized Model M case ready and waiting. I'd go for the full "kit" as I don't want to use any of the parts from my wonderful Model F AT.

Posted: 18 Sep 2016, 19:40

by UnFocused

Techno Trousers wrote: As it stands now you may need one, depending on the final outcome of Phosphorglow's resin molding experiments.

Wait... is he planning on making his own SSK cases?

Posted: 18 Sep 2016, 19:49

by regack

UnFocused wrote: Techno Trousers wrote: As it stands now you may need one, depending on the final outcome of Phosphorglow's resin molding experiments.

Wait... is he planning on making his own SSK cases?

Check out this post from a few pages back :

viewtopic.php?f=7&t=13796&p=327410#p327410

Posted: 18 Sep 2016, 23:15

by snoopy

Posted: 19 Sep 2016, 13:06

by BinaryHalibut

Huh, for those of us too poor to have an SSK case, two adhesive rubber feet on the bottom plus two capped bolts up top actually looks to be a pretty good system.

Looking forward to this

Posted: 19 Sep 2016, 18:16

by drevyek

BinaryHalibut wrote: Huh, for those of us too poor to have an SSK case, two adhesive rubber feet on the bottom plus two capped bolts up top actually looks to be a pretty good system.

Looking forward to this

The trouble is with the controller on the bottom. You'd need some sort of shield for the controller, as well as a receptacle for the connector board, all of which basically means that you'd need the bottom of the case anyways, unless a custom part was made.

Another option, what I've done, is to cut down an M case to the SSK form factor. Unicomp sells spare M cases for pretty cheap, and all you'd need else is a dremel or saw. It isn't too tough, but requires a bit of patience with the plastic.

Posted: 19 Sep 2016, 18:23

by alh84001

@lot_lizard how exactly is the PCB <-> controller connection gonna be made?

I know there were mentions of a slot connector, but what I'm wondering is, will that come attached with new PCBs from the PCB service or will it be available separately? I'm asking because I would like to reuse my PCB for this project, since it has a relatively low serial number, but I would also like the benefits of the slot connector.

Posted: 19 Sep 2016, 19:49

by wcass

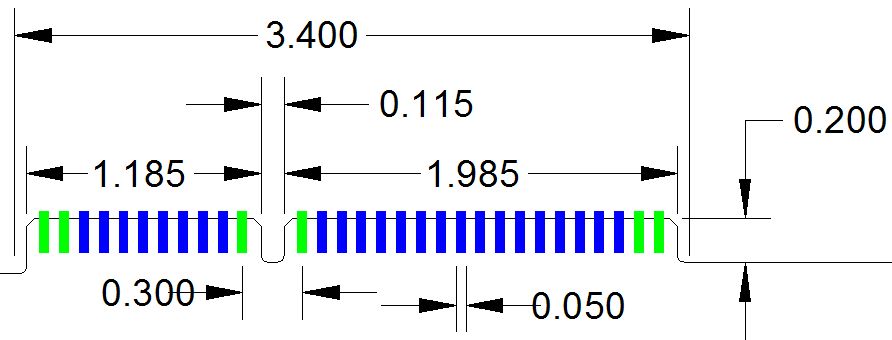

The original PCB has controller pins set at 0.156" pitch. Then new controller has pins set at 0.1" pitch with some notches left, right and between rows and columns. I'll post a drawing of the top of PCB later.

Posted: 19 Sep 2016, 20:00

by BinaryHalibut

drevyek wrote:

The trouble is with the controller on the bottom. You'd need some sort of shield for the controller, as well as a receptacle for the connector board, all of which basically means that you'd need the bottom of the case anyways, unless a custom part was made.

Another option, what I've done, is to cut down an M case to the SSK form factor. Unicomp sells spare M cases for pretty cheap, and all you'd need else is a dremel or saw. It isn't too tough, but requires a bit of patience with the plastic.

I mean, as long as you aren't shoving it in your backpack or something the controller should be fine hanging there. And I think the xwhatsit has a micro usb connection on it anyways, so the connector board isn't even needed if using it caseless.

That said, it's not a

great option. Just

an option. And the stainless steel floating-key look isn't half bad.

Posted: 19 Sep 2016, 20:03

by lot_lizard

alh84001 wrote: I'm asking because I would like to reuse my PCB for this project, since it has a relatively low serial number, but I would also like the benefits of the slot connector.

Fortunately for most (but not for us with original PCBs), the new controller and PCB won't be interchangeable with the original version. The real reason is because we are changing the connector pitch from .156 to .100. The previous PCB will work perfectly fine with everything else, but you will still need the legacy F xWhatsit if you are planning to reuse the original PCB.

EDIT: WCass beat me to it. Typing on the phone is brutal

The new PCB will have a slip-on (slot) style connector very similar to the beamsprings, and the new xWhatsit will be similar to beamspring xWhatsit (except the connector will be inverted so the controller sits behind the backplate as opposed to above). Both will have the connector pitch shrunk to .1

I plan on using my original PCBs like you (for multiple reasons). The only functional difference will be the winkeys and split spacebar are missing (no bigs). I do like the direct solder inverted approach I used with header pins. Really cleaned it up

Posted: 19 Sep 2016, 20:09

by Wodan

lot_lizard wrote:

Giggity!

Posted: 19 Sep 2016, 20:27

by lot_lizard

BinaryHalibut wrote: I mean, as long as you aren't shoving it in your backpack or something the controller should be fine hanging there. And I think the xwhatsit has a micro usb connection on it anyways, so the connector board isn't even needed if using it caseless.

That said, it's not a

great option. Just

an option. And the stainless steel floating-key look isn't half bad.

No reason it wouldn't work well. It is on the same tangent as the Phase 2 "floating board" idea. There the controller would live inside the stand, with the stand being hidden from most angles.

If you wanted to try your hand at designing a 3d print (or out of wood) versus just hardware parts... My suggestion would be to make a little stand at the back that covered the controller, and was secured with the two ground screws. Then make it run forwards towards the front of the board so that it lifted the front edge to the desired height. Could be very attractive if done patiently, and certainly cheaper than sourcing an SSK shell.

Lots of options, and always backwards compatible with the Model M shell. Make it your own... Why not right?!?

Posted: 19 Sep 2016, 21:30

by fohat

BinaryHalibut wrote:

And the stainless steel floating-key look isn't half bad.

Since I created the "naked" option a couple of years ago, I use this F-122 far more than I use the ones with the cases.

A simple bottom pan would be good, and wood might offer some good qualities, too.

Posted: 19 Sep 2016, 22:09

by lot_lizard

@Fohat... Nice repurposing of an XT badge. Case-less is certainly fun

Couple of updates

- Picking up our 8 additional XT's tonight (along with a free Selectric 1 typewriter that powers on, but doesn't function otherwise... These are typically easy fixes, and become little gifts for my journalist friends)

- WCass... Got the caps you pictured a few posts ago. I will experiment on a few junker caps first, but think this could be very promising

- Cindy is sending me 5ish F122s sometime this week to add to the pool, and her friend should have SEVERAL more boards for us now that they have sorted out the Blue and APL keys. We saw him selling the good stuff before and thought all was lost. He doesn't want to eBay anything not pristine and easy to flip it seems

- I will be getting the Buckling Spring Selectric cap set any day now, and will take some better pics

Posted: 20 Sep 2016, 03:07

by wcass

For anyone interested, the two connectors together are 3.4" wide including the slots at the ends and between rows and columns.

- controller connector.jpg (37.91 KiB) Viewed 5444 times

Posted: 20 Sep 2016, 08:54

by alh84001

wcass wrote: The original PCB has controller pins set at 0.156" pitch. Then new controller has pins set at 0.1" pitch with some notches left, right and between rows and columns. I'll post a drawing of the top of PCB later.

Ah yes, I completely forgot about that. Thanks.

Posted: 20 Sep 2016, 14:06

by POTV

Will it be possible to choose between ISO and ANSI?

I'm actually most used to ISO on IBM Model M. But ANSI seems to have a less noisy enter key - less rattle when pressed down - compared to most of my IBM Model M's. Probably because of the smaller size and simpler construction...

Posted: 20 Sep 2016, 14:10

by alh84001

With IBM it doesn't matter. You just have to have proper keycaps and stabiliser inserts (I don't think the plate will have stabiliser hooks). Barrel position are the same for both layouts.

Posted: 20 Sep 2016, 16:55

by lot_lizard

The spoils of yesterday. All are in pretty good shape really (though dirty), with the AT being a very pleasant surprise.

- image.jpeg (1.73 MiB) Viewed 5302 times