Re: Recreating the Lisp keyboard (10 years later)

Posted: 22 Feb 2021, 01:15

those sound so good! very lovely look and sound both

mechanical keyboard authority

https://ns1.deskthority.net/

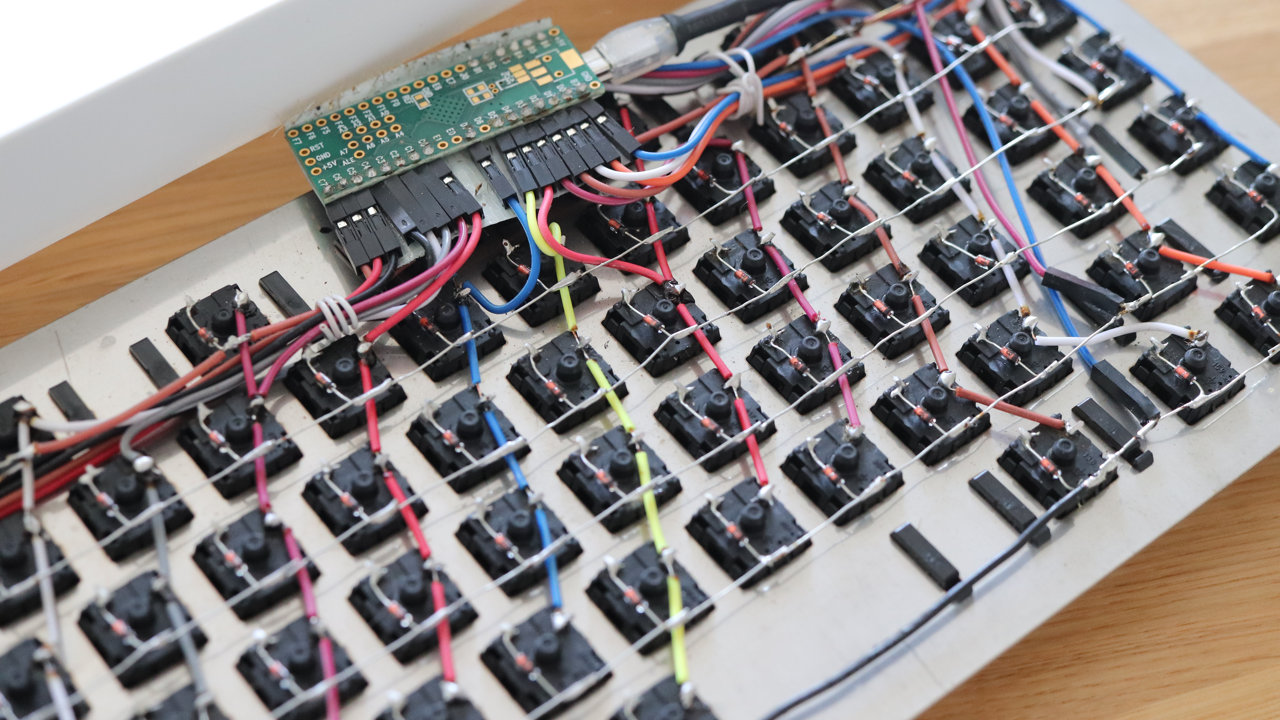

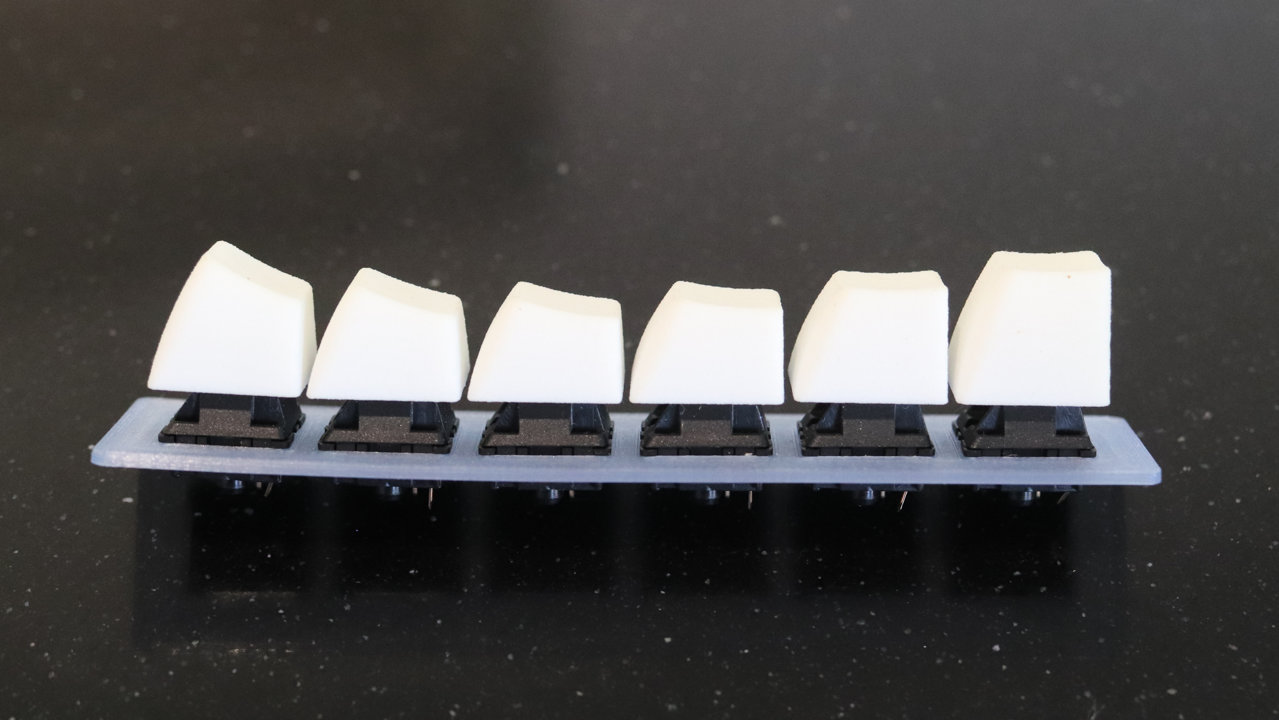

Music to my ears. What a great sounding board.lispnick wrote: 21 Feb 2021, 18:03 Hi guys! I have made a quick sound comparison to give you an idea of the difference between my keycaps and the more traditional Alps-mount keycaps. I have used a subset of trapezoidal PBT keycaps that came from the IBM PC Convertible. The demo shows the results on a board that has NeKtar-lubed green alps under the hood.

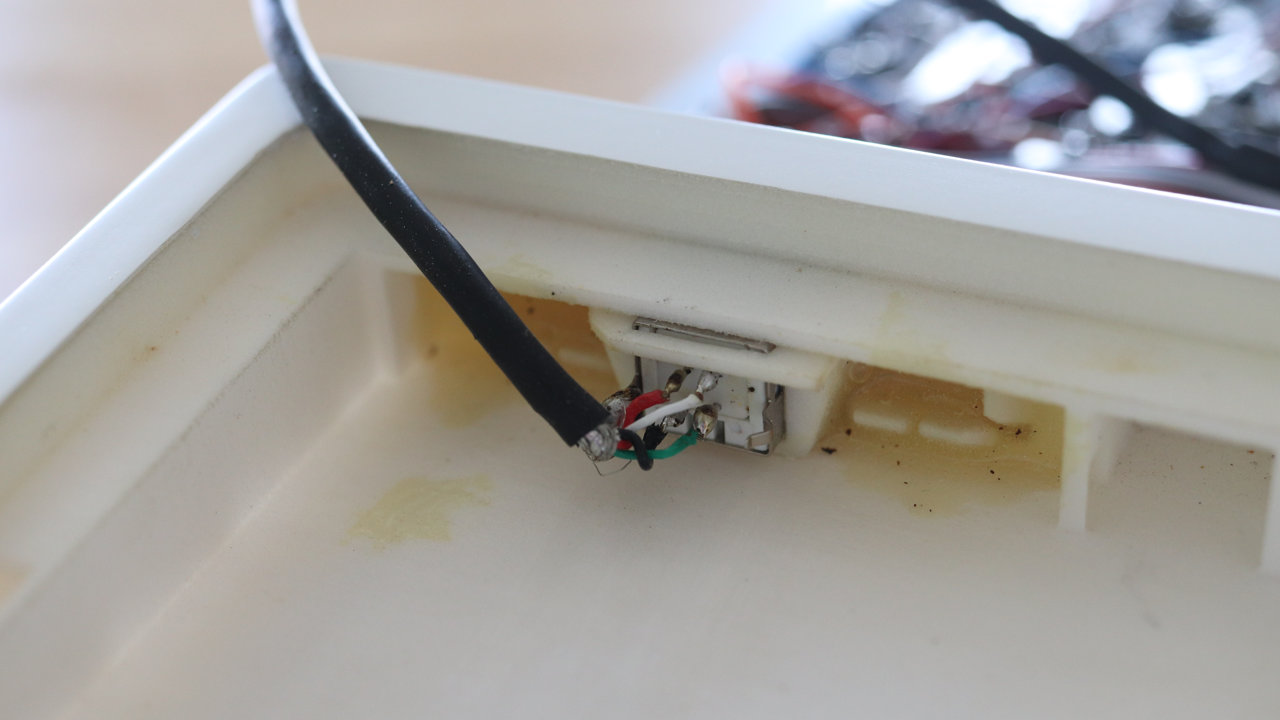

While the Blue Alps are really good, especially the spacebar; I'm surprised by how good the Matias Click switches sound as well (I can barely notice the click, so sounds more like tactiles to me)!lispnick wrote: 16 Mar 2021, 14:47 I have finished building the board on Blue Alps. I think this is a nice opportunity to compare the sound of the switches with Matias Clicks in the same case. Here is the result:

Yes, the Matiases are much louder and in my opinion sound better in the combination of all-metal case and these thick keycaps.zoo wrote: 16 Mar 2021, 19:18While the Blue Alps are really good, especially the spacebar; I'm surprised by how good the Matias Click switches sound as well (I can barely notice the click, so sounds more like tactiles to me)!lispnick wrote: 16 Mar 2021, 14:47 I have finished building the board on Blue Alps. I think this is a nice opportunity to compare the sound of the switches with Matias Clicks in the same case. Here is the result:

I am humbled! Of course, none of this would have been possible without many of you guys and the resources on Deskthority. Thanks!XMIT wrote: 16 Mar 2021, 21:11 lispnick, this is one of the most exciting developments I've seen in a very long time. Kudos to you. If we have Deskthority Awards (which we had damn well better this year) you have my vote!

My funds are going toward the elecplus warehouse cleanout, I hope to be able one of your kits in due time.

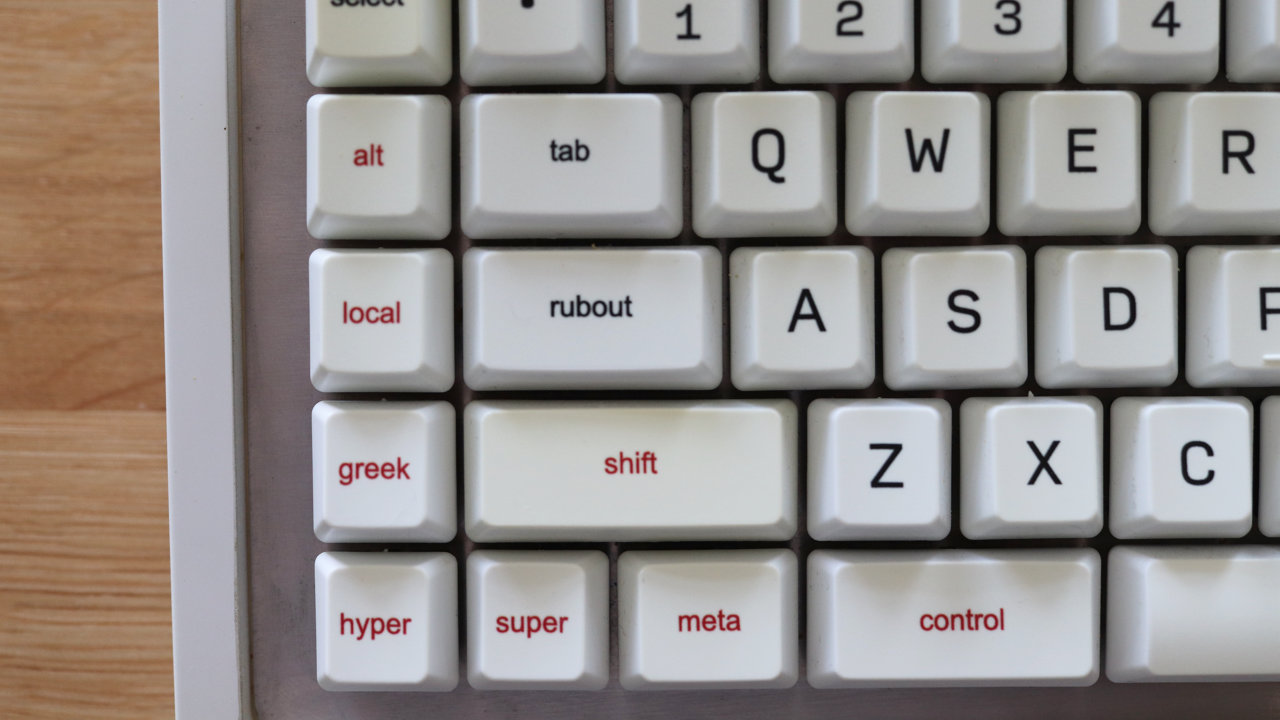

This was one of the biggest dilemmas during the development—custom legends on the grey keys.MMcM wrote: 17 Mar 2021, 00:12 Ooh, I'm pretty sure that Blue Alps one is headed this way; very excited.

It remains to be seen whether I remember where are all the function keys are without legends.

The material has Shore hardness 70D, so it is a bit softer than ABS. It can be scratched but I did not experience that during a standard use (I use mine about a year as the main keyboard).MMcM wrote: 01 Apr 2021, 18:31 Got it out of customs. Here it is with a senior relation.

A620N-364000.jpg

It's interesting; there is a bit of scuffing on the L key. Probably not visible in the photo. I'm not bothered by it, but now I'm curious what happens after the key caps get used for a while. What have you found?

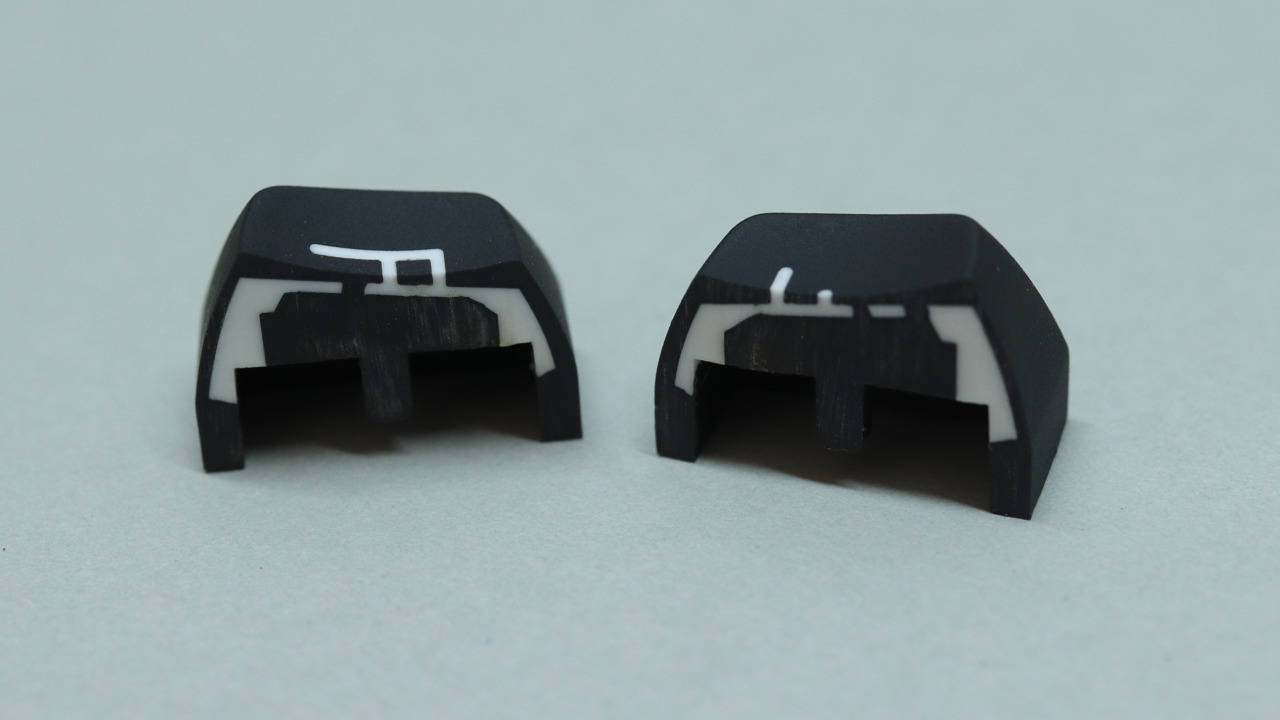

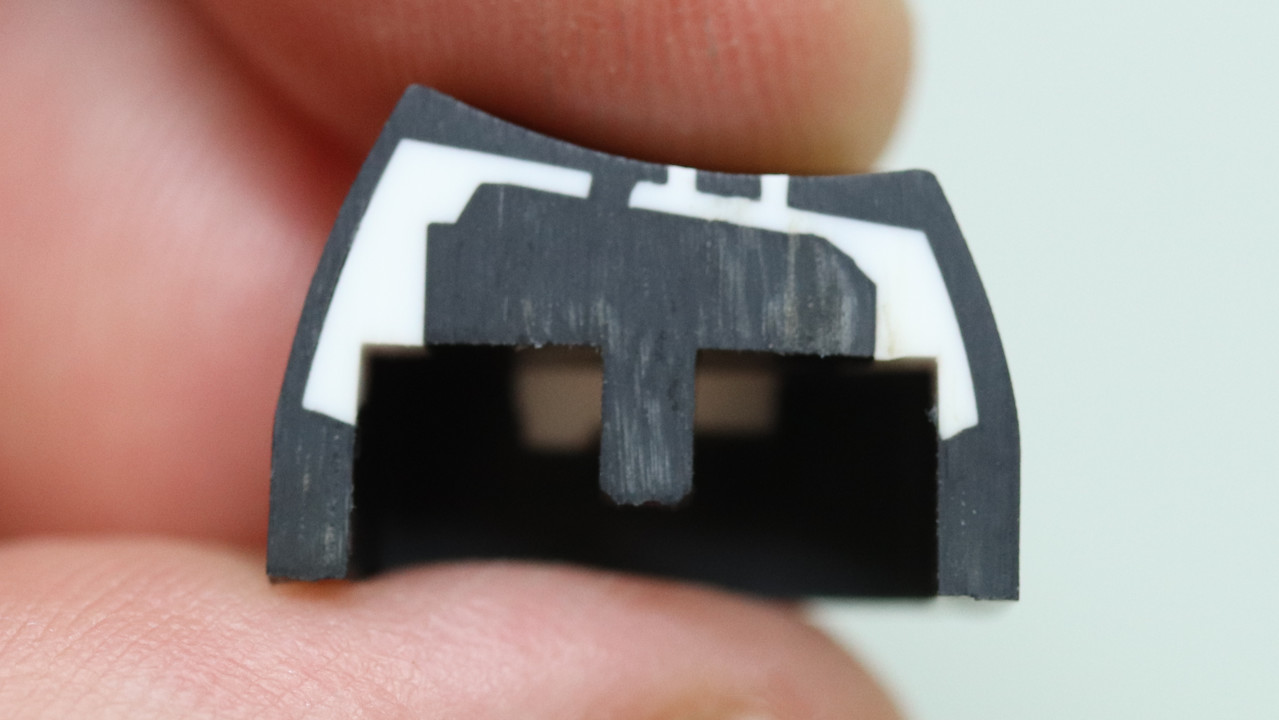

Interesting! Do you know the exact depth of the engraving?runninghack wrote: 15 Apr 2021, 20:26

also want to share this pic here about the custom legends.

The caps in the pic were laser engraved and filled with resin-like materials.

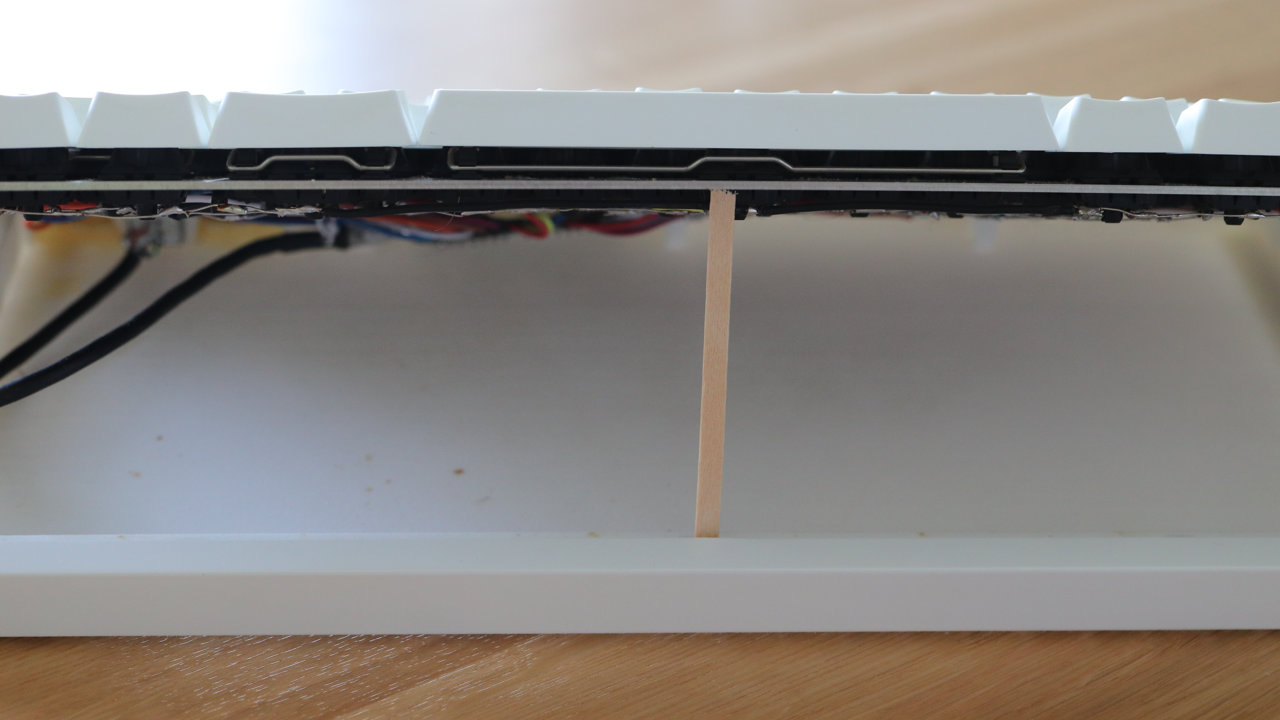

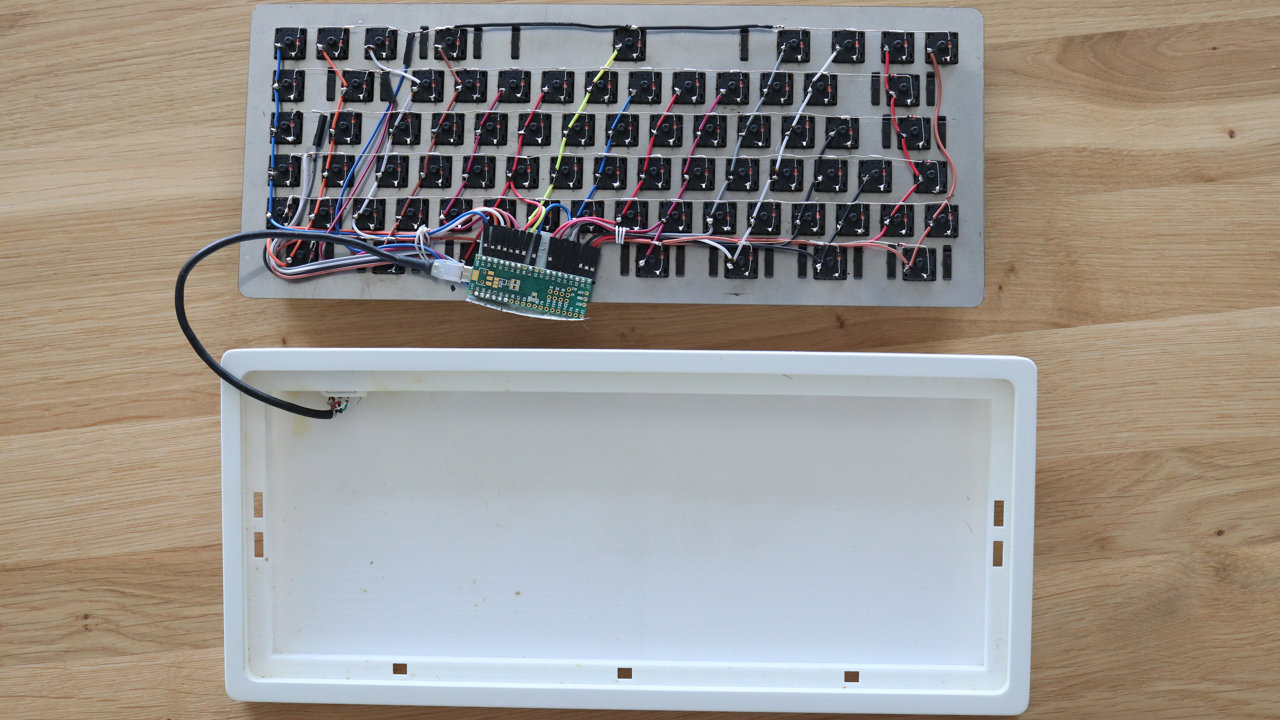

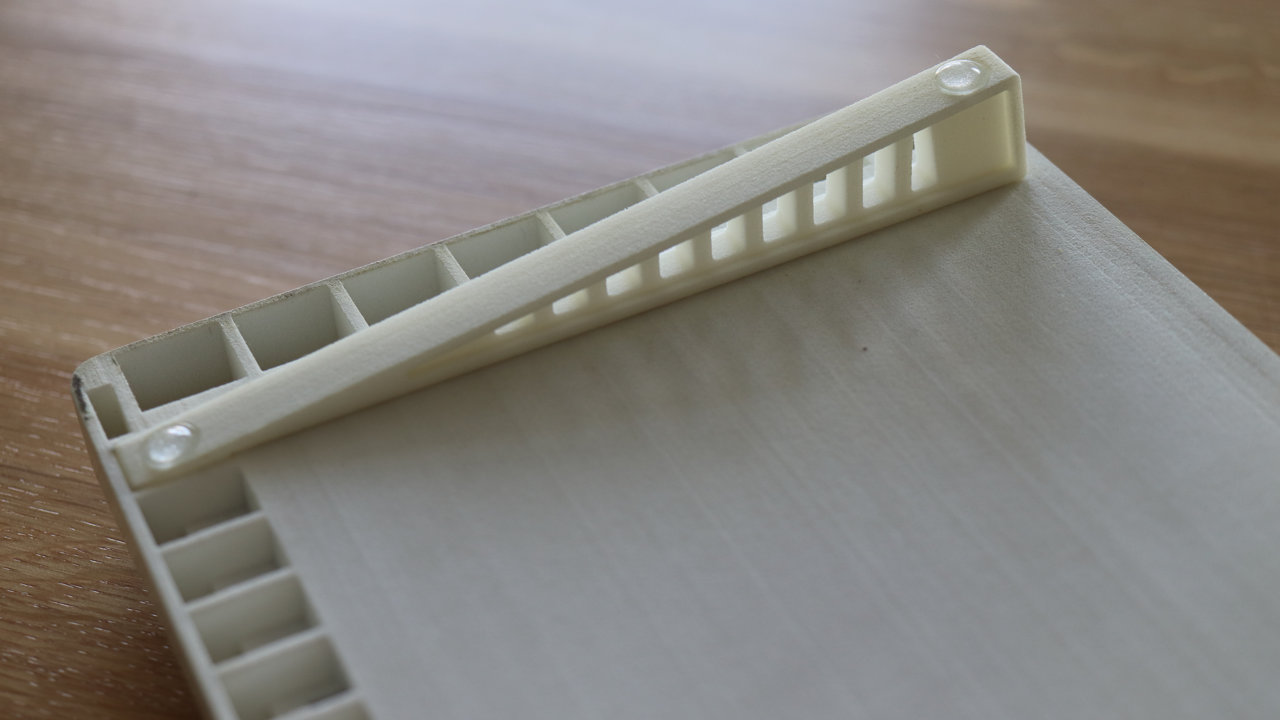

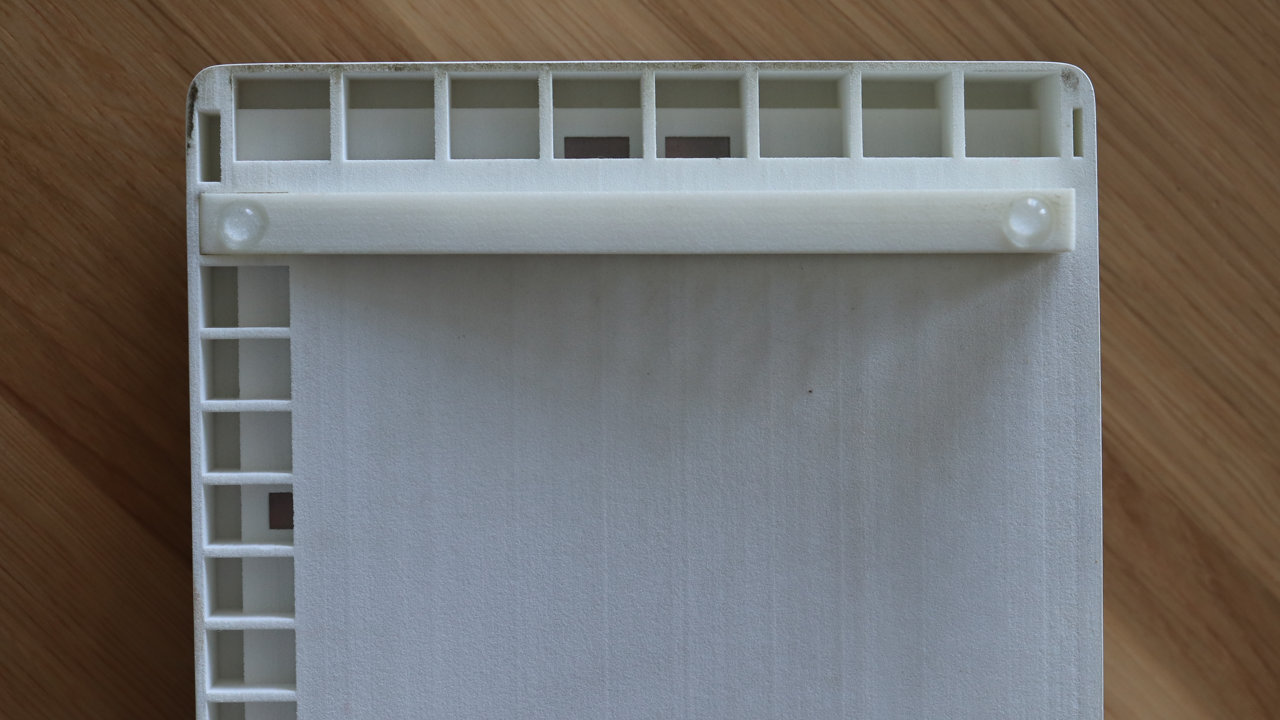

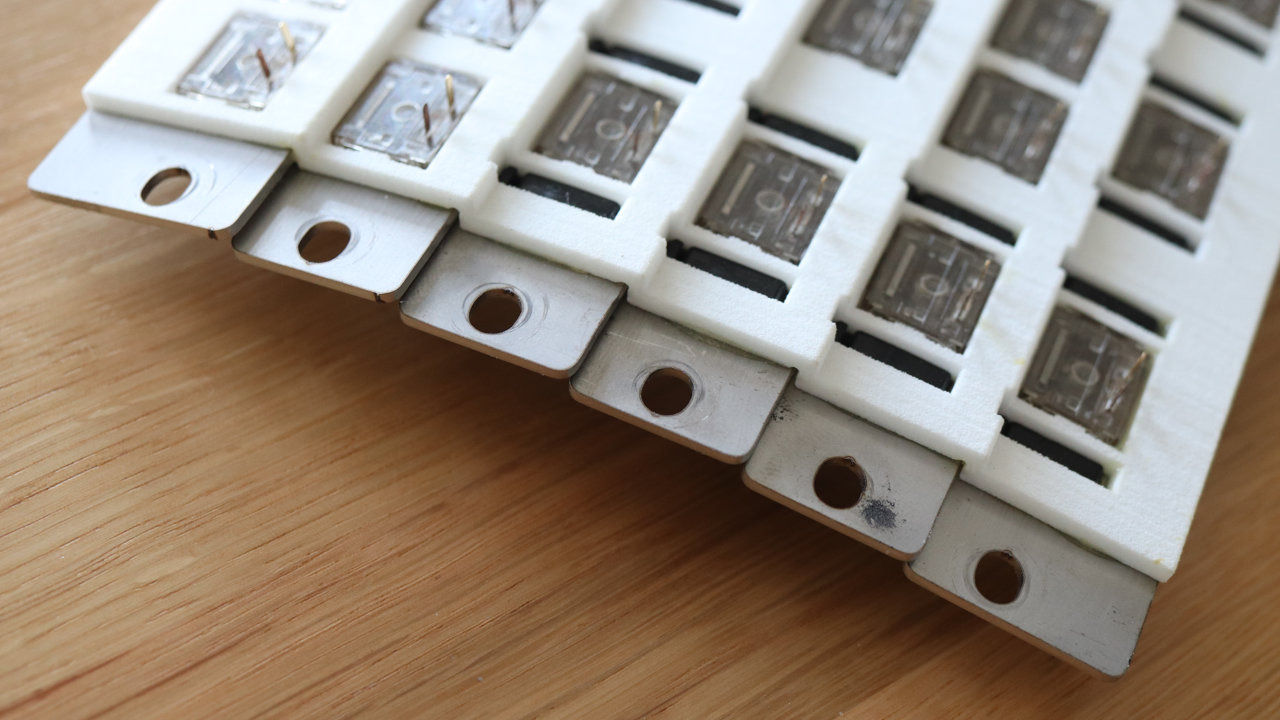

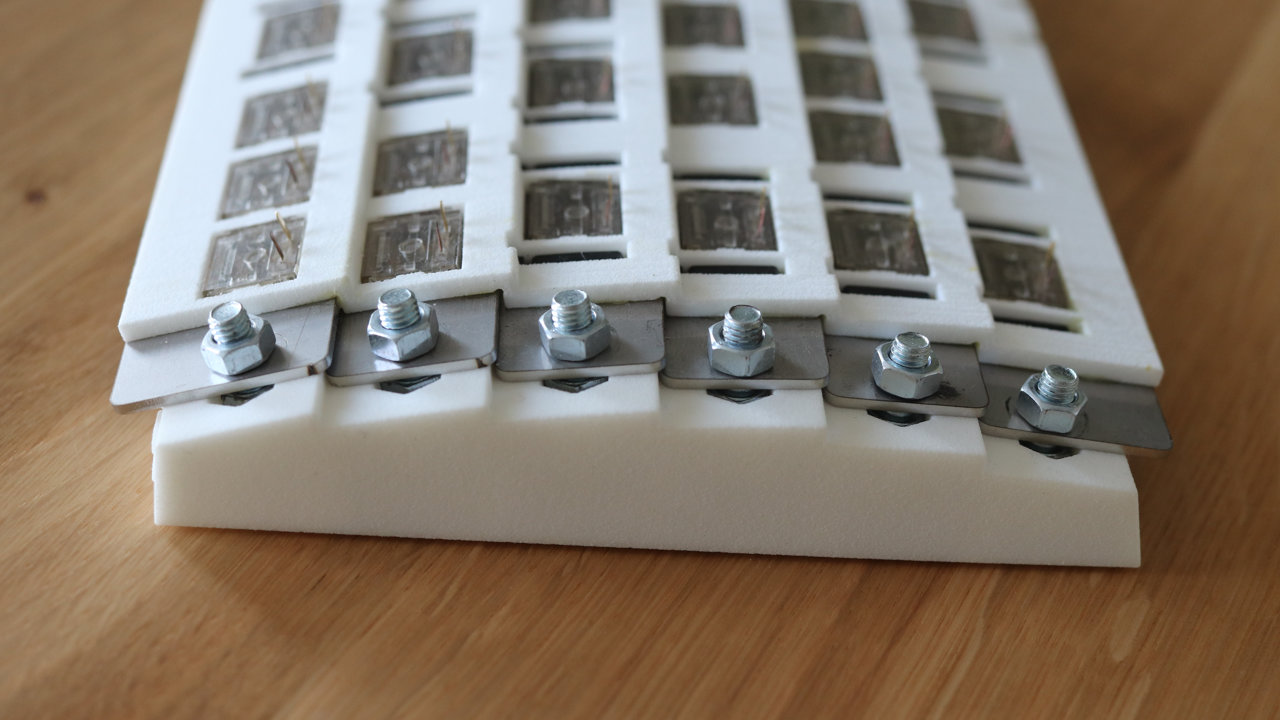

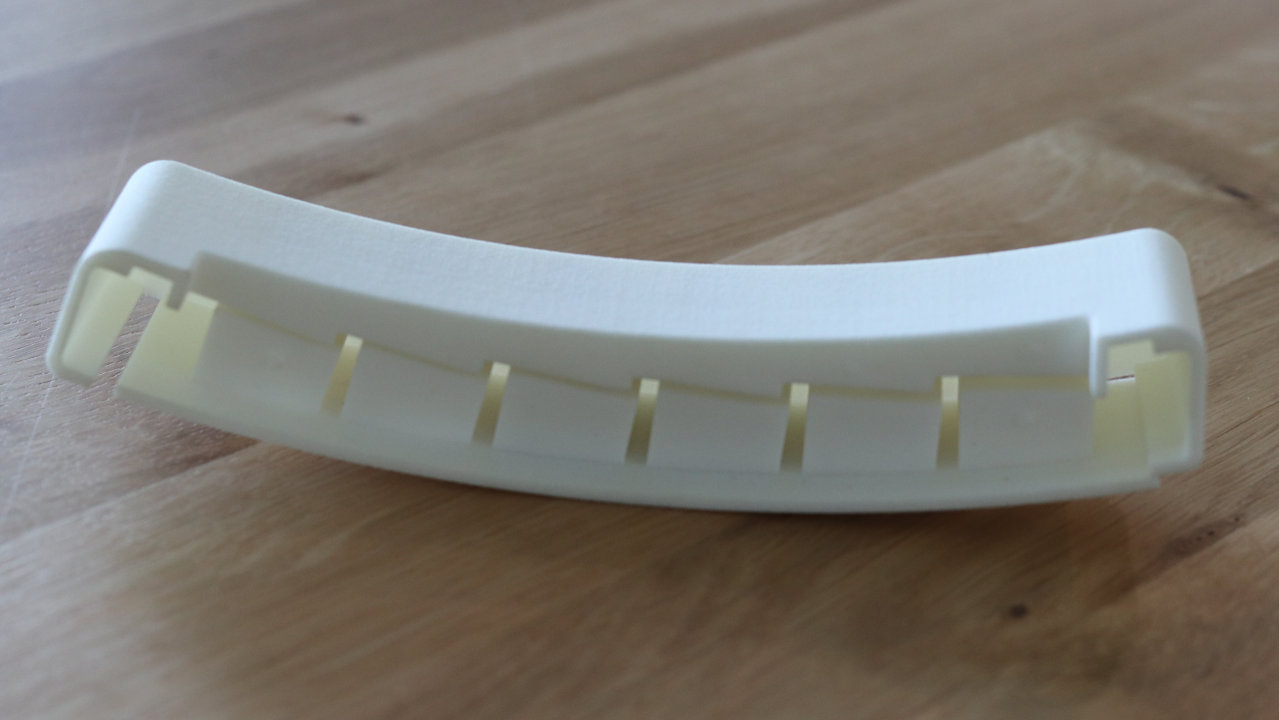

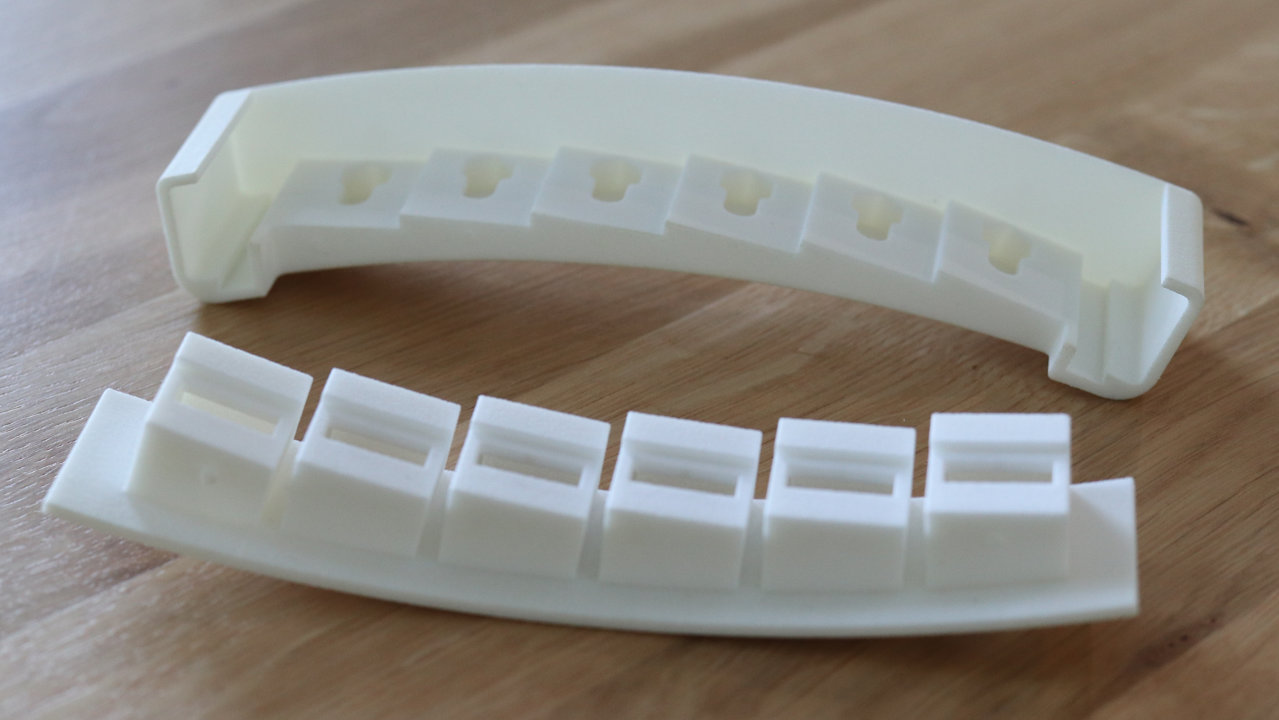

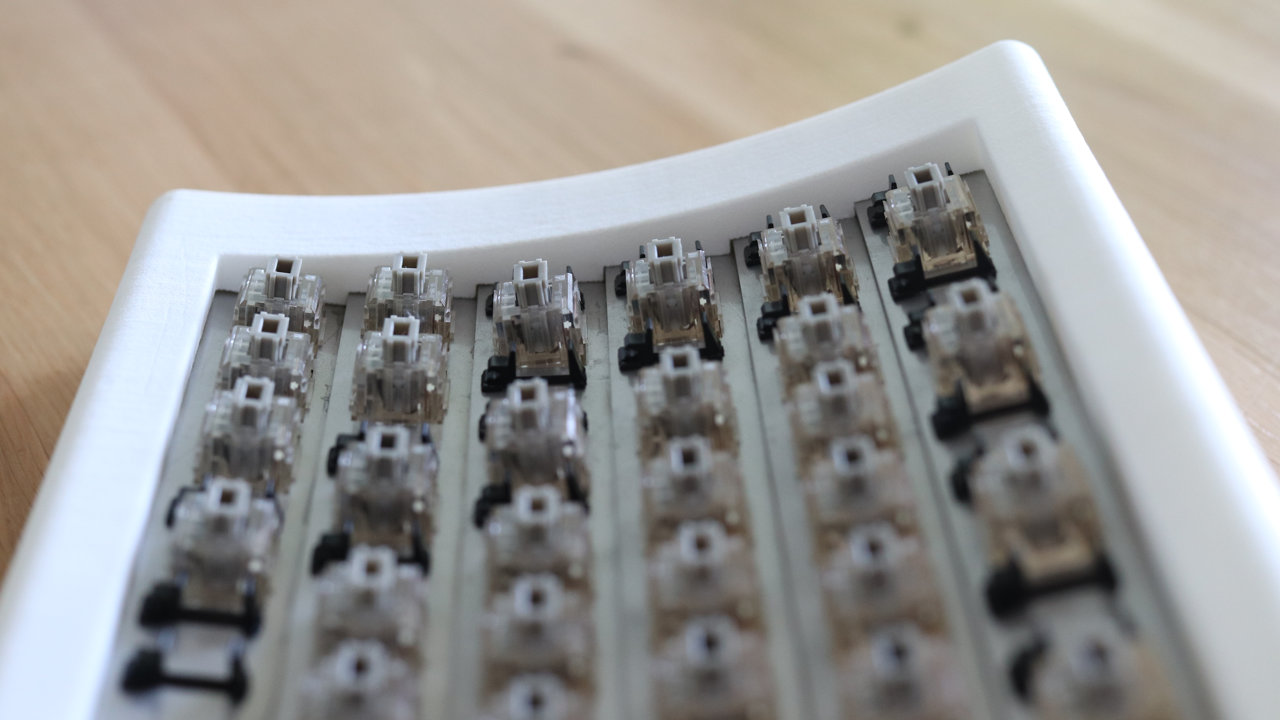

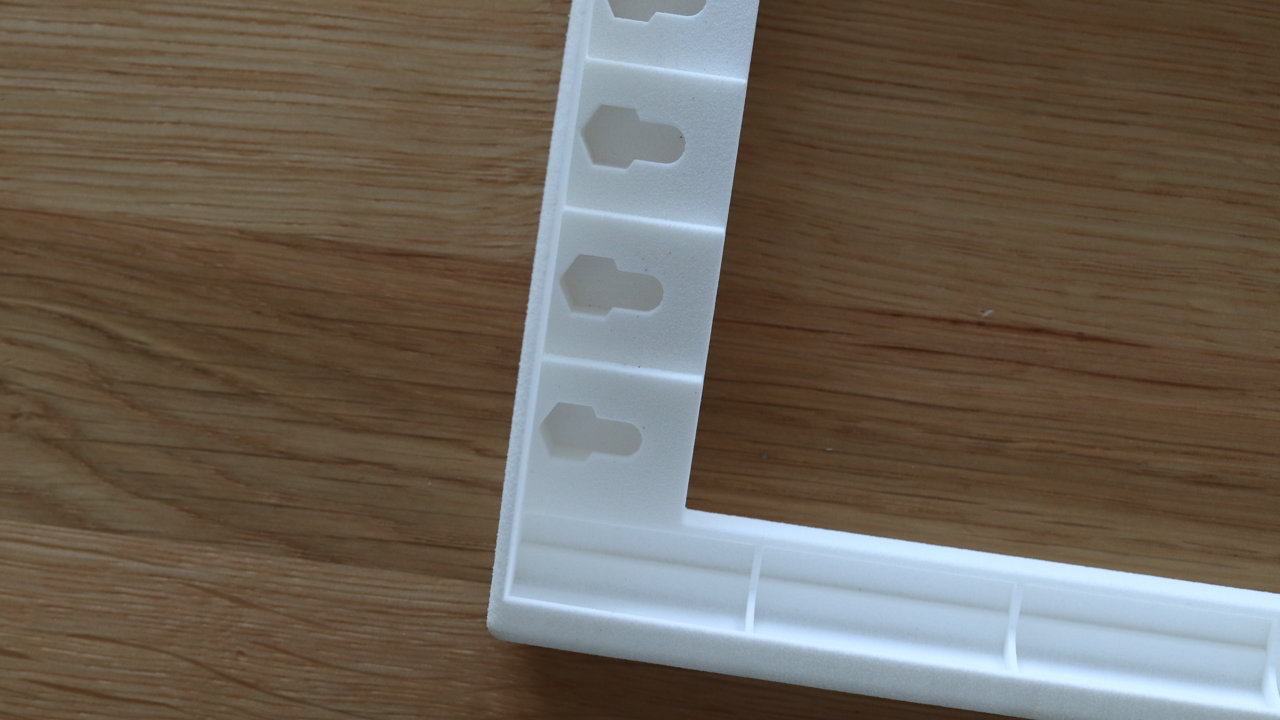

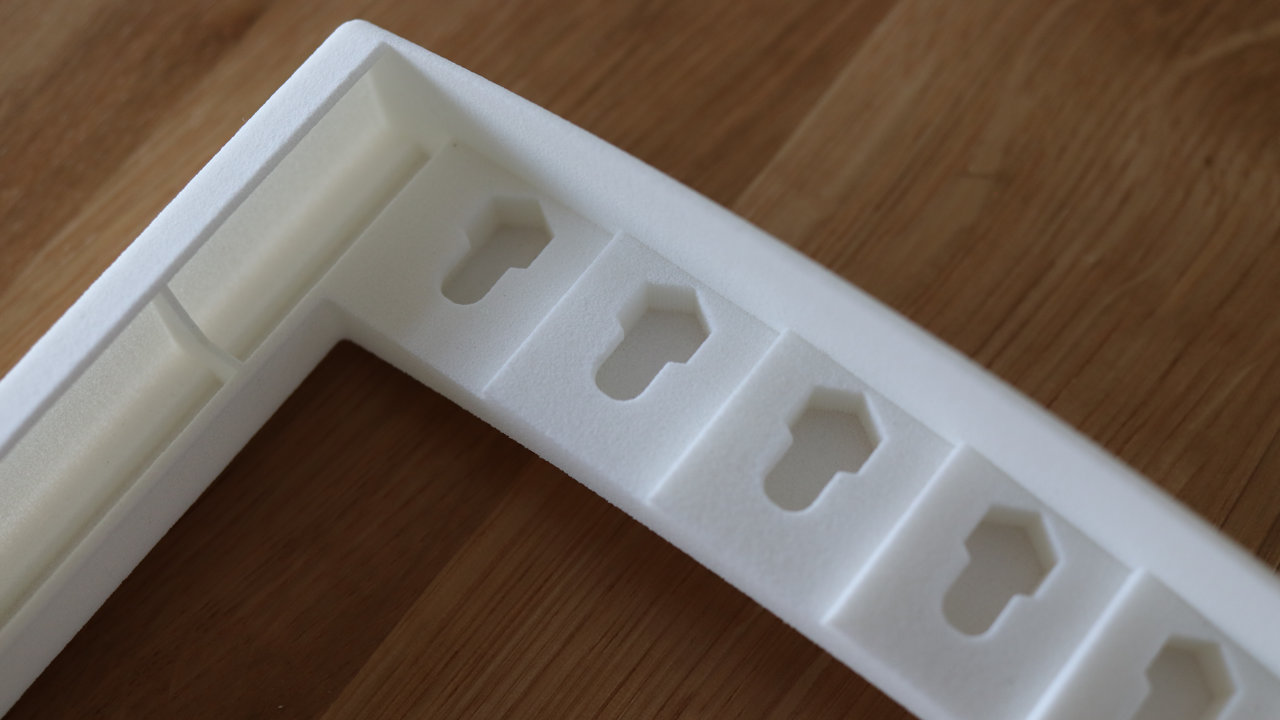

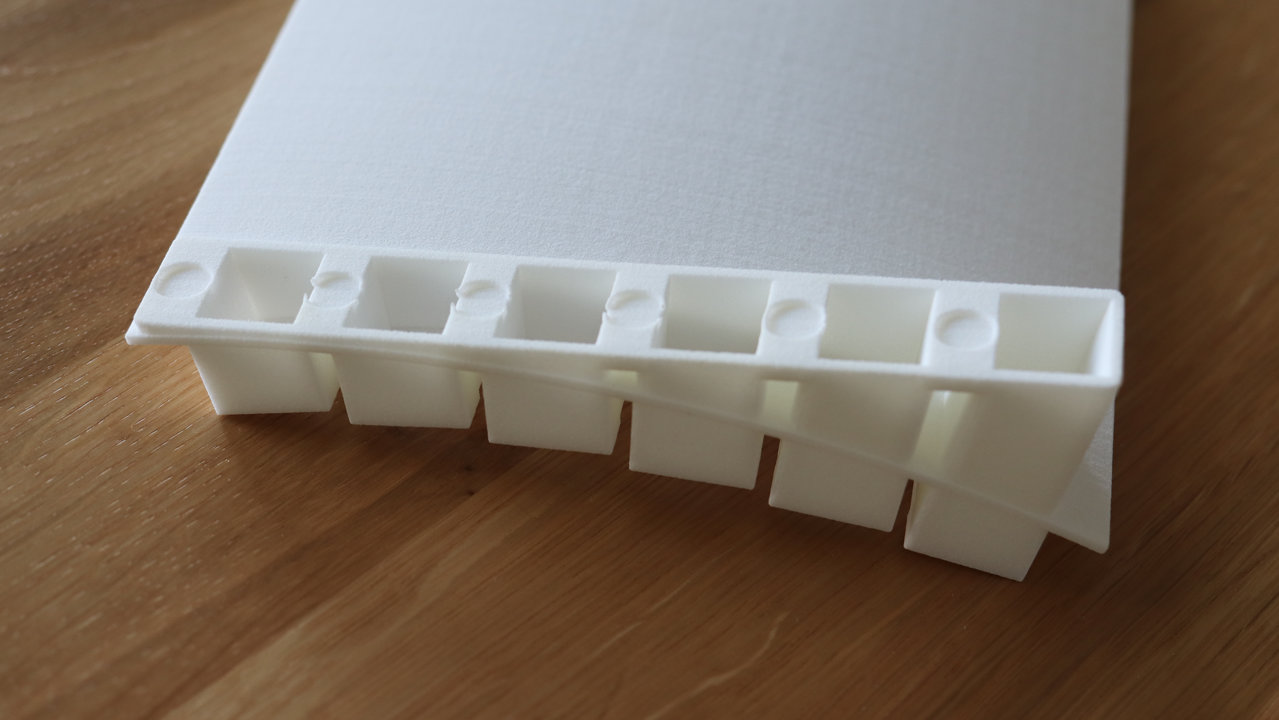

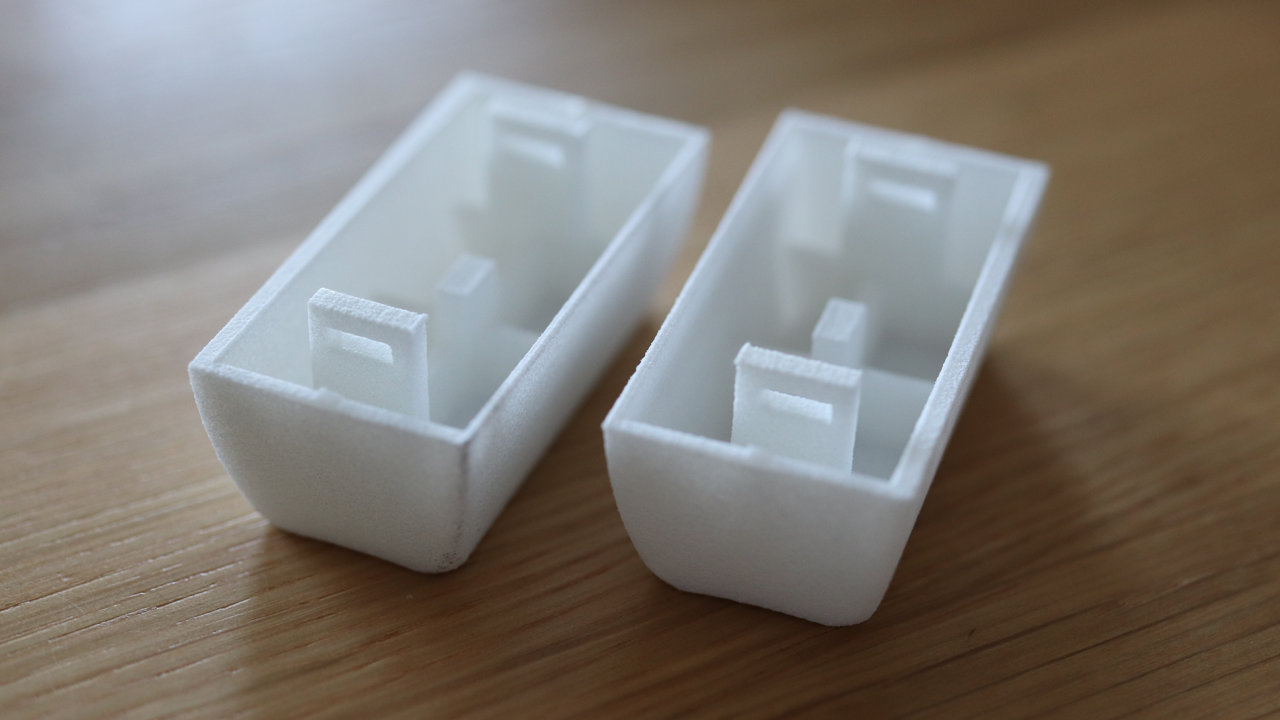

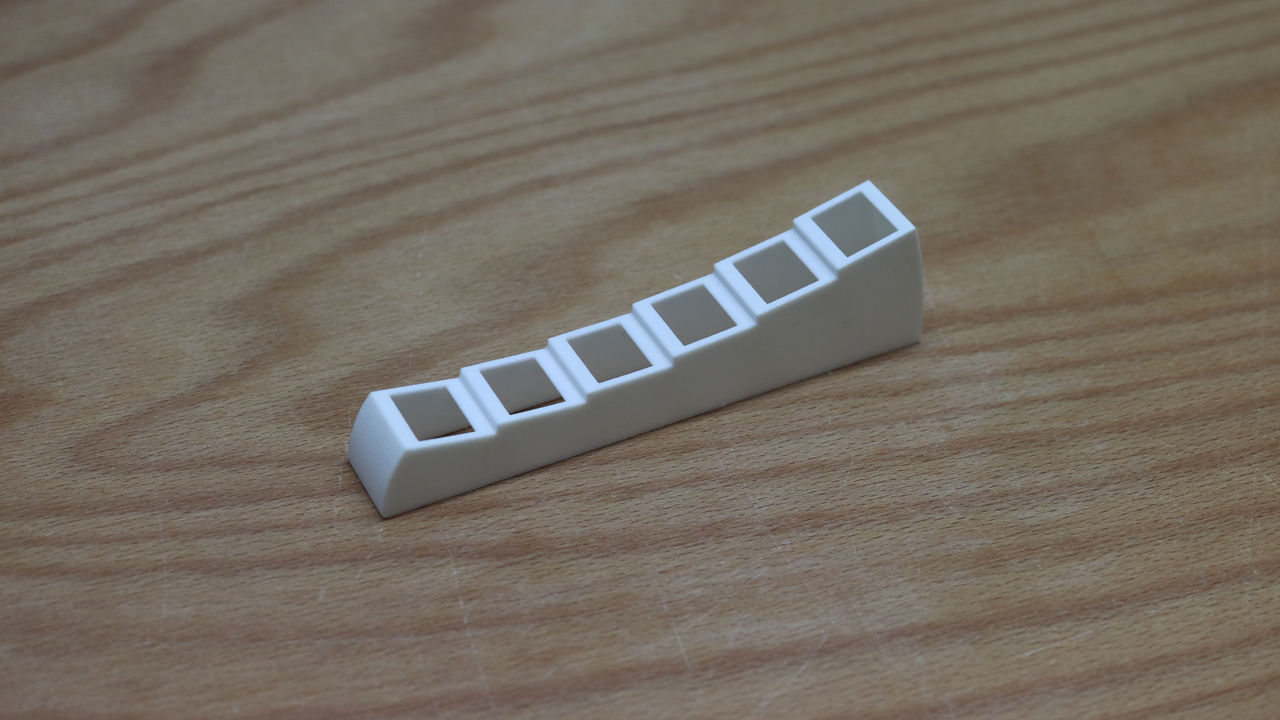

I started with making this model:Rayndalf wrote: 16 Apr 2021, 01:41 That curved plate is genius (and gloriously overengineered).

How did you model the plate step + curve in Fusion360? I tried something similar and I really just eyeballed it after a point.

Just asked the manufacturer about it. They said the depth is around 0.5mm.lispnick wrote: 19 Apr 2021, 00:42Interesting! Do you know the exact depth of the engraving?runninghack wrote: 15 Apr 2021, 20:26

also want to share this pic here about the custom legends.

The caps in the pic were laser engraved and filled with resin-like materials.

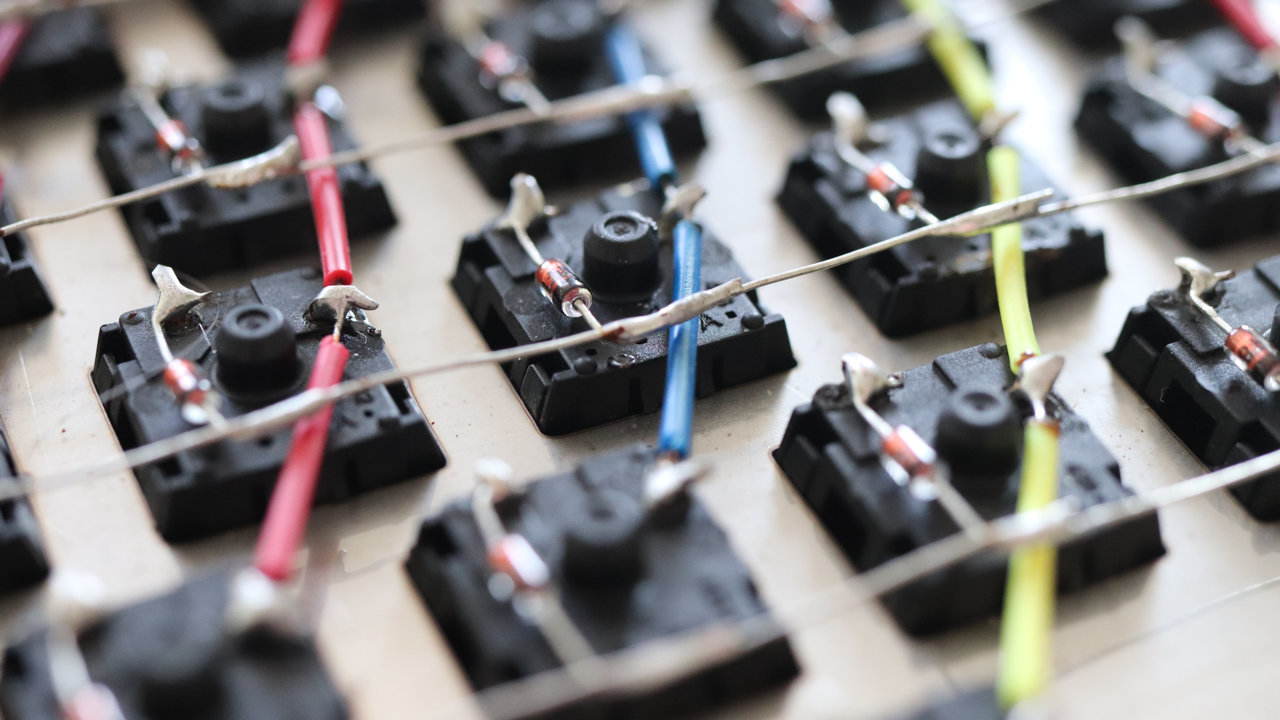

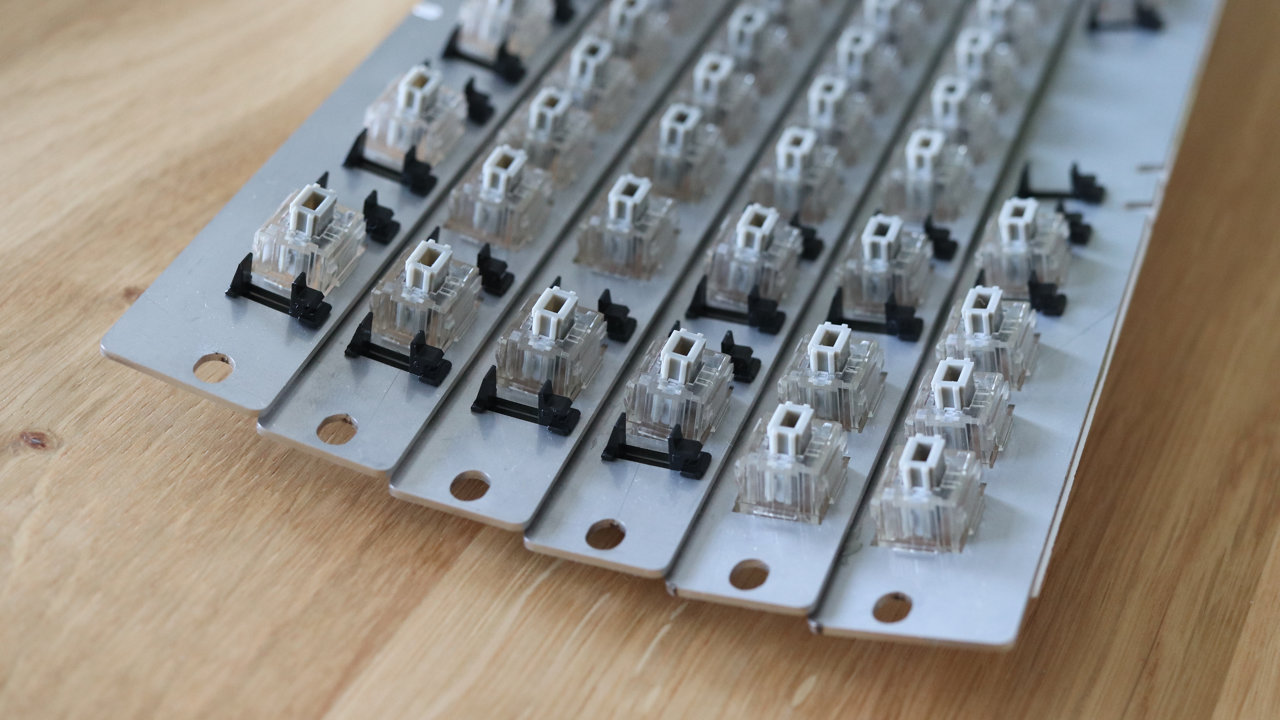

Handwiring + individual plates for each row would be extremely flexible, especially if each plate "strip" was mounted to the upperside of the case with gaskets.runninghack wrote: 19 Apr 2021, 03:51 The stepped mount plate is a great idea. I wonder why you want to use the 3d-printed skeleton though. Right now most of the custom keyboard designers and users lean to use soft plates (PC plate/half plate) and mounting methods enable soft bottom out (gasket/PORON+leaf-spring).

Your solution by its nature is superior than all of the existing approaches as the plates (and the PCBs if there are six PCBs I assume) are totally separated.

Of course it's a matter of preference and some people like sturdy plates. Just want to bring it up as no one has discussed it so far.