Page 3 of 73

Posted: 26 May 2016, 10:35

by Khers

Why not add support for both barrel types? They only differ by the placement of the alignment mark so should be as easy as making three holes in the plate per barrel rather than two, right? Then we would have the freedom to use any barrel of our choice.

Ultimately, I'd prefer to get new barrels (and flippers, but I'll soon have extras of those) as I would otherwise have to slaughter up a perfectly useable keyboard and one that I'm rather fond of.

Posted: 26 May 2016, 10:45

by lot_lizard

Khers wrote: Why not add support for both barrel types? They only differ by the placement of the alignment mark so should be as easy as making three holes in the plate per barrel rather than two, right? Then we would have the freedom to use any barrel of our choice.

Excellent idea. I'll make the top plate and foam have cutouts for both, and then it is flexible. It still doesn't solve the supply issue of the barrels, but should cater to all available. I believe there are only the two designs?

Posted: 26 May 2016, 12:46

by Muirium

Tying ourselves to Ellipse as a provider is sheer bloody madness. And not the good kind! I vote very firmly against that, and for our own supply. Which we control, own the molds for, and are free from his profiteering.

Like surely most buyers of this project: I'll need a complete set of barrels and flippers provided for this. XTs etc. are rarer and much more costly to ship around this side of the sea. Besides, harvesting multiple keyboards for their guts is icky. This is an elegant project, let's make it possible for all comers, without all that mess.

Posted: 26 May 2016, 13:03

by andrewjoy

It would be nice if it was all open i agree, what i want is a simple drop in replacement , buy the barrel frame with all the F bits in it , slap it in a model M case ... DONE!

Re: Remodeling the Model M

Posted: 26 May 2016, 21:51

by Techno Trousers

I would love to have our own ongoing supplier of barrels, flippers, and springs that could be used in multiple group buys going forward. As I see it the main problem with relying on ellipse's supplier is that he's made it clear that as soon as round two is over, it's over for good. Sure, getting them for a lower cost is a great bonus, but I have a feeling that once this project really gets going it'll draw a lot of interest, and being able to meet that demand without sacrificing tons of old school Model Fs would be nice.

Posted: 26 May 2016, 21:53

by Muirium

Indeed. There's no upside that I can see in relying on Ellipse. He's got plenty on his plate already. Let's make this a group effort instead. Something we control, and so can run again and again whenever required in the future.

Posted: 26 May 2016, 22:34

by idollar

Guys,

As promised and after testing the FEXT I post ALL THE FILES that you need to modify/improve/order.

Do not hesitate to ask any question.

BTW: I plan to help with this project and any other similar, as far as it remains a real open project, with all sources available for improvements. This is what a community should be.

Posted: 26 May 2016, 22:48

by andrewjoy

Muirium wrote: Indeed. There's no upside that I can see in relying on Ellipse. He's got plenty on his plate already. Let's make this a group effort instead. Something we control, and so can run again and again whenever required in the future.

We could always see if he is willing to make public the barrel and flipper stuff , i mean if round 2 is the end of his thing then he has no more use of them

Posted: 26 May 2016, 22:55

by lot_lizard

andrewjoy wrote: We could always see if he is willing to make public the barrel and flipper stuff , i mean if round 2 is the end of his thing then he has no more use of them

This is a guess... so take with a grain of salt. I think he might have worked out a cost structure where the mold is owned by the manufacturer. It is cheaper, and they are giving you a reduced rate on tooling with the assumption there is a possibility you will return in the future. I don't know this is the case, but if he knew he was only making 2 runs, and could give approximate numbers to them, it is definitely something that would have been quoted (often optimal on short runs). So really... his hands might actually be a little tied. Again, all a guess based on how I know this process works

Posted: 26 May 2016, 22:58

by lot_lizard

idollar wrote: Guys,

As promised and after testing the FEXT I post ALL THE FILES that you need to modify/improve/order.

Do not hesitate to ask any question.

BTW: I plan to help with this project and any other similar, as far as it remains a real open project, with all sources available for improvements. This is what a community should be.

Yay... awesome work. I will verify against my plans, and then create some renders to publish. I am not sure if I have ever said it in this thread (I know I have in others)... just like i$, my follow-on work will be open as well. I will publish once I am as comfortable as he is

Again... outstanding work, and thanks again for making all of this possible

Posted: 26 May 2016, 23:40

by Ratfink

Muirium wrote: Tying ourselves to Ellipse as a provider is sheer bloody madness. And not the good kind! I vote very firmly against that, and for our own supply. Which we control, own the molds for, and are free from his profiteering.

Hey now, what exactly is wrong with a guy trying to run a business? Ellipse's prices aren't low, but he knows what he's doing and puts in a good amount of work. Surely that deserves compensation.

Posted: 27 May 2016, 00:33

by lot_lizard

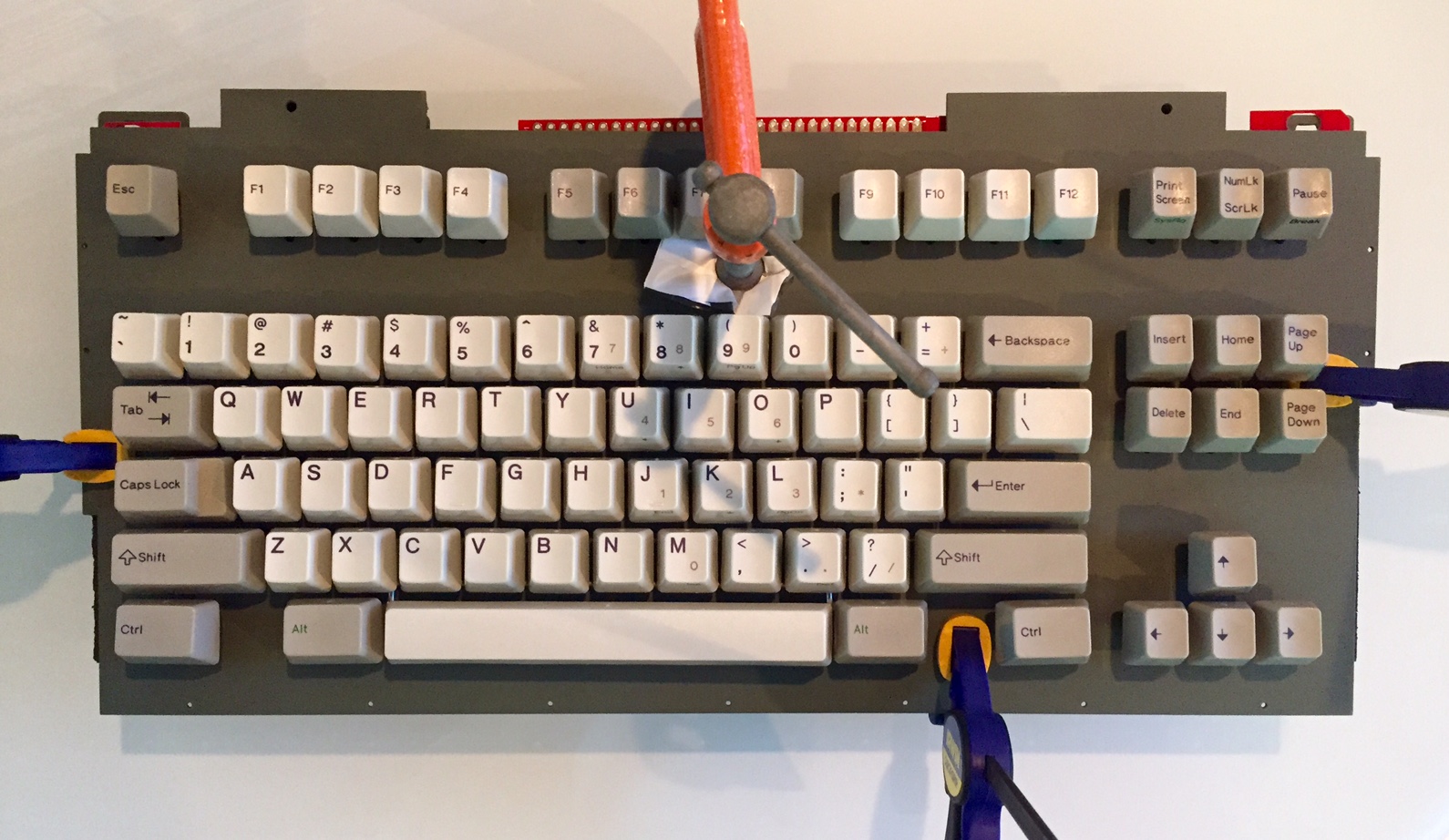

So... I am a very happy person

Click here,

workshop-f7/remodeling-the-model-m-t137 ... ml#p308666

And search for "EDIT: Flat plate testing!!!" (base of the second OP) to find out why. Spoiler alert (this WILL work)

Posted: 27 May 2016, 00:46

by emdude

Wow, this is looking incredible, I think it is becoming exceedingly clear that the potential for this project extends much farther than simply having a drop-in replacement for existing Model M keyboards.

Posted: 27 May 2016, 00:56

by Muirium

Progressing very nicely. Rewarding stuff already, congrats!

Ratfink wrote: Surely that deserves compensation.

Working with him is fine. If he shares his design materials with us, great, and respect to him. But gifting someone with more of an eye on hype and profit the power of veto over our future work is a no go. Especially if he's serious about permanently killing his production. That's daft.

Posted: 27 May 2016, 03:03

by lot_lizard

emdude wrote: Wow, this is looking incredible, I think it is becoming exceedingly clear that the potential for this project extends much farther than simply having a drop-in replacement for existing Model M keyboards.

Muirium wrote: Progressing very nicely. Rewarding stuff already, congrats!

Thanks... I am probably most excited about this Cherry cap stuff because it is so different than we have been able to do up until now (anything new is fun), and to be frank... our cap options suck (Ellipse's current hang-up). Eyes on the prize first though... the drop-in with modifications to promote the future where possible (the barrels).

I am done with the FEXT plans. Just generating renders now, and they should wrap up sometime this evening or early tomorrow. I will post them, order the jetted top plate for the FEXT, and then take a week long break. i$ just sent my FEXT PCB out today, so the timing should work out nicely. I will process the plates (bend, break, tap, etc) for both the SSK and 101-key at the same time.

Posted: 27 May 2016, 17:00

by lot_lizard

We now have the FEXT assembly plates

Click here to view the details:

workshop-f7/remodeling-the-model-m-t137 ... ml#p308667

Also, if you missed the update regarding flat plate testing, it was very fruitful. Click here for details, and scroll down in the post for the update:

workshop-f7/remodeling-the-model-m-t137 ... ml#p308666

Re: Remodeling the Model M

Posted: 27 May 2016, 19:55

by Techno Trousers

Flat plate bucking spring just blows my mind. I'm still in love with the classic IBM curved plate and key profile, but I'm also really interested to hear what the experience of typing on a flat BS board with adapted cherry caps is going to be like. I'm guessing it will be almost identical to a modern Cherry switch board, but with a Model F feel? Wow.

Question, though. In your update, you mention that the front of the barrels needs to be lowered to use them flat. Does that mean two different barrel types are needed, one for curved and one for flat? Or will the"flat-optimized" barrels work with the traditional curved plate?

Great work on all of this lot lizard. I wish I had the knowledge, time, and resources available to experiment like you are.

Posted: 27 May 2016, 20:25

by lot_lizard

Techno Trousers wrote: Question, though. In your update, you mention that the front of the barrels needs to be lowered to use them flat. Does that mean two different barrel types are needed, one for curved and one for flat? Or will the"flat-optimized" barrels work with the traditional curved plate?

I'm glad you brought that up. I went back and reread, and the description is not clear (I confused myself

), and I will re-word in the OP.

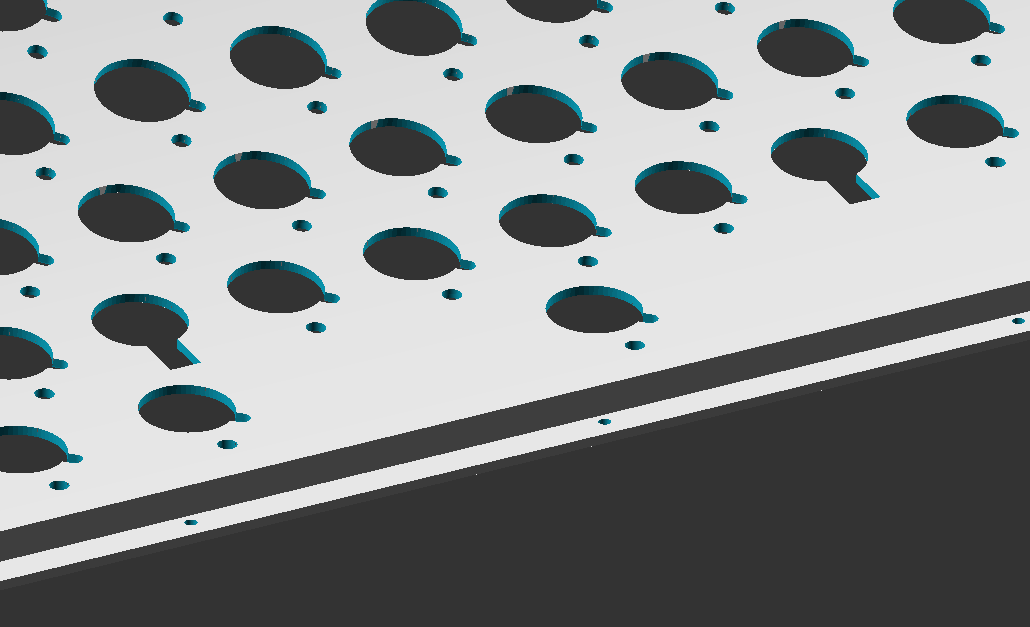

The moral is this... the keys are tighter sitting together inside the radius of a curved plane (our backplate). So the closer you get to the origin of a radial bend (further from the circumference, closer to the center of the circle), the tighter the compression. I'll edit this picture later with a better one, but for now (pretend the keyboard is upside down)...

So since our buckling spring keys sit above the curved plane, the distance between key rows are reduced. Tightening the rows by approximately ~.5mm. When you flatten the plane, the key rows are then spread. The problem is that the barrel bases are still touching (or very close to it)

So we need to reduce the Y dimension (assuming you are sitting in front of the keyboard, and the width is the X) of the barrel by .5mm to account for the lost key compression (stems are now perfectly vertical). Luckily though, the barrels are oversized in that dimension in relation to the flipper. We could remove .5mm off the front of the barrel base (or .25mm off either side of the Y axis), and still not impact the flipper inside in any way. Ideally when we produce barrels, we make them have a smaller Y dimension profile to allow them to work for both (flat or OEM curved).

For flattening (not the barrel, but the flipper), the flipper itself is angled to contact the PCB pad evenly on the curved plane. If we reduce the curved plate, we also need to flatten the angle of the flipper that contacts the PCB to account for the change (through testing, this is not a requirement, but is obviously ideal). Based on testing, we should be able to produce flippers that satisfy both needs fairly easy.

Make sense? I know that is wordy, but this type of stuff is not the easiest to describe in text...

EDIT: And again, this is just testing to see if we can. We might not ever proceed down this path, but we wanted to test while the opportunity was there (biggest question... how much of a wobbly mess would the board be). It was more structurally sound that I anticipated. The keys felt incredible (as good as the curved plane), there is zero perceivable flux in the middle of the board, and the audible feedback is basically identical throughout the board. We would still want to bend the top plate slightly to apply down pressure evenly across the keys if we were really doing this, but with only 4 points of compression (uneven), it performed famously

Re: Remodeling the Model M

Posted: 27 May 2016, 21:27

by Techno Trousers

Cool, thanks for that detailed explanation--it makes sense to me now. I'm really enjoying my popcorn and watching all this unfold!

Posted: 28 May 2016, 00:46

by lot_lizard

If I could ask a favor of someone... Both i$ and I are really wanting this to be a community effort. WCass has gotten us well on our way with really unique case badge (still working out all legality issues there), but to be honest, we can circle back to the badge at a later point with a separate group buy.

One thing we really are going to need is some sort of sticker for the back of the assembly. I borrowed this image from a SSK that Madhias sold here as an example (hope he doesn't mind)

I would really like it if someone else took that on, and get creative with it. There are a few stipulations to abide by, but otherwise free reign, and be willing to accept direction from the community if they would like to see improvements:

- Do not use the IBM logo. In the end, this potentially has zero actual IBM parts left for the drop-in assembly, and that would be infringement (no question). Even if this is non-profit

- A part/model number. I really do love the idea of 1391337 that HAL used as his April Fool's joke (and XMIT suggested for this project)

- Some sort of serial number to uniquely identify each assembly

- Some sort of "born on date" (feel free to use a better term)

Anything else... be creative. Maybe a QR code so we can laugh about how that technology isn't used 20 years from now, whatever...

Your contribution will be appreciated, and there are no bad suggestions

EDIT: Also, assuming this would have just happened anyway, but there should be a DT logo valiantly displayed with pride. This project was born here, and deserves endorsement. Webwit has previously approved the use of our logo for these types of projects per personal request, and he provided the following url if you are looking for the

official image

Posted: 28 May 2016, 17:43

by Spaceman1200

Progress on this has been nuts, Keep up the good work guys. Can't wait to see the outcome

Posted: 29 May 2016, 02:30

by Techno Trousers

If it's not too late, I'd like to take up the gauntlet on the label design. How do you feel about file formats, lot_lizard? I can do it in docx format easily, but I can also go out and get LibreOffice if people would prefer the open format. I do like the idea of the 1391337 part number for an inner part label label like that. Since this is pretty much a Model F reproduction, what about part number 6011337 that can be used on an outside case (whether a drop-in replaced innards, or a newly manufactured case)?

Posted: 29 May 2016, 03:08

by lot_lizard

Techno Trousers wrote: If it's not too late, I'd like to take up the gauntlet on the label design. How do you feel about file formats?...

Since this is pretty much a Model F reproduction, what about part number 6011337 that can be used on an outside case (whether a drop-in replaced innards, or a newly manufactured case)?

Nice... We can't wait to see. The inner sticker would be the priority, but certainly up for the outer as well. You will be able to use the IBM logo on the outer case only (at least for the drop in). I hadn't even thought about part numbers for the outer sticker, but if everyone likes, I'm game for anything. Appreciate you stepping up

EDIT: File format can be absolutely anything you are comfortable in, and can make frequent changes to based on the feedback here. We can easily convert anything into anything else as needed

Posted: 30 May 2016, 19:37

by lot_lizard

Updates have been made to the FEXT assembly plate post

workshop-f7/remodeling-the-model-m-t137 ... ml#p308667

Surmised: The rendering was corrected to match the version that was actually ordered, and a small video was added to show how a press brake will be used to provide the ~4mm offsets on the upper and lower edges of the top plate

Posted: 01 Jun 2016, 21:02

by lot_lizard

Khers wrote: Why not add support for both barrel types?

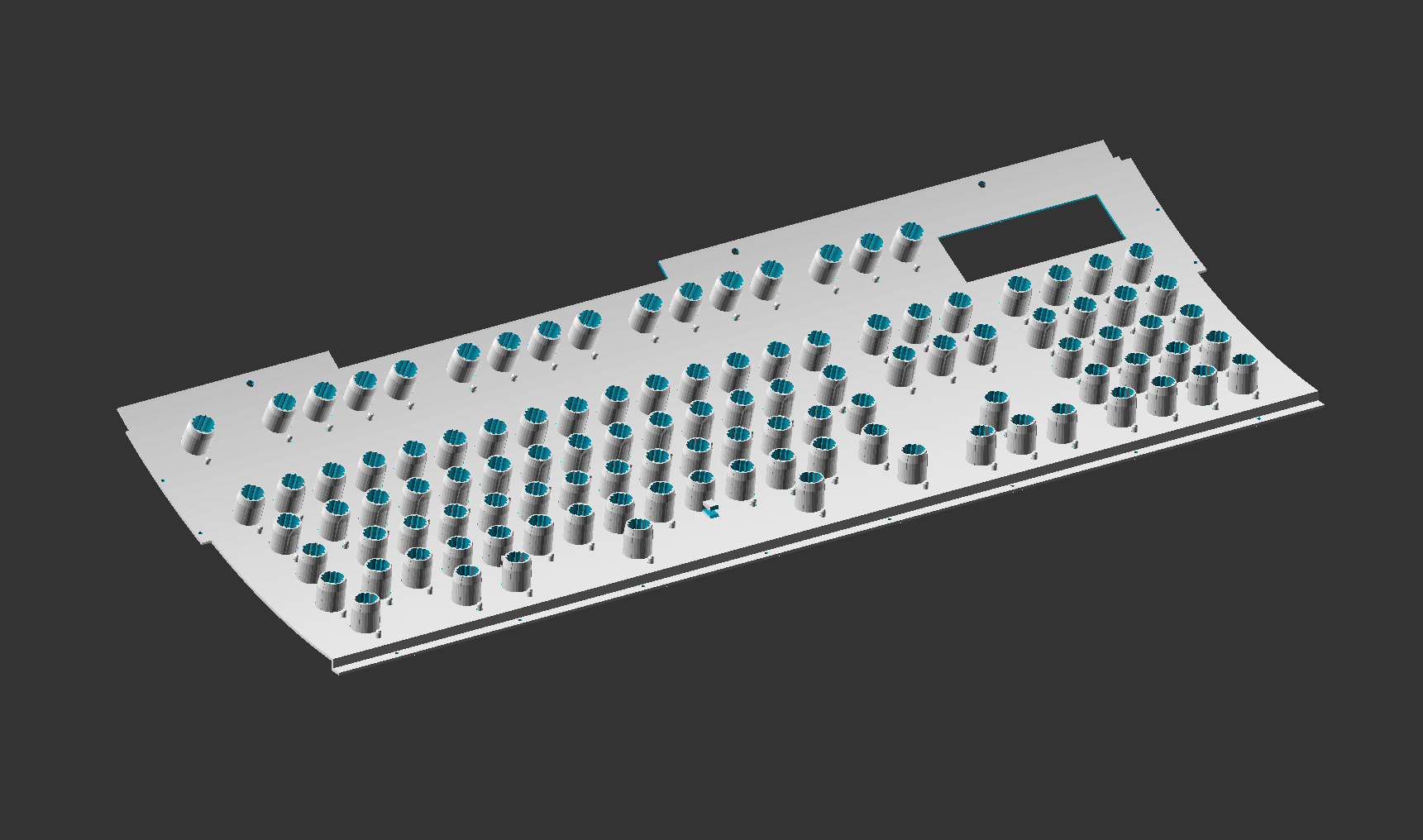

The top plates for the 84 and 101 key layouts have updated cutouts to support both types of F barrels. This hybrid cutout won't be on the functional metal prototypes I am putting together in the coming weeks, but will be available going forward after that. So this opens up the opportunity to use 4704, F122, and Ellipse barrels until we can get the barrel production bit sorted out. Attaching renders of the 101-key only below, but will eventually update the OP's. Also, the Big Blue Saw order for the 101-key top plate was just shipped. Should have some progress there early next week.

- topPlateHybridBarrel.png (41.45 KiB) Viewed 6573 times

Additional renders (close-ups, etc.)

Posted: 01 Jun 2016, 21:34

by emdude

The thought did not occur to me until now, but I think you will need additional stabilizer cutouts for the '+' and the 'Enter' keys on the numpad to support the early Model Ms (1390131s, 1390120s, and early 1391401s) which used wire stabilizers for those keys.

Posted: 01 Jun 2016, 21:41

by lot_lizard

emdude wrote: The thought did not occur to me until now, but I think you will need additional stabilizer cutouts for the '+' and the 'Enter' keys on the numpad to support the early Model Ms (1390131s, 1390120s, and early 1391401s) which used wire stabilizers for those keys.

Awesome catch. It should be easy enough to have the inverted version of the current stabilizer barrel (those were likely going to be Acrylate prints anyway because of the cost of another mold). My prints for them deliver this week, and will know for sure. Again... great catch

Re: Remodeling the Model M

Posted: 01 Jun 2016, 23:49

by Techno Trousers

Weren't there going to be barrel openings between ctrl and alt for 1x Windows (or other) keys, or am I confusing this particular render with the addition of those pads on the FEXT PCBs?

Posted: 02 Jun 2016, 00:04

by lot_lizard

Techno Trousers wrote: Weren't there going to be barrel openings between ctrl and alt for 1x Windows (or other) keys, or am I confusing this particular render with the addition of those pads on the FEXT PCBs?

For sure... I've been lazy. I'll clean all these renders up (with those extra keys), and get the OP's updated when I get home this weekend. Should have a few updates with the prints FINALLY being delivered on Friday (scheduled) as well.

Side note... I did procure a few feet of sample .156 pitch ribbon cable (15 core, so you would need 2 cables per current FSSK/FEXT PCB). I am giving some to i$, but will have a little left. It's impossible to find, so if anyone would like a little... PM me

Posted: 02 Jun 2016, 10:38

by vsev

Immediately literally in love with very amazing work here,

Saving wallet for GB !