Page 32 of 308

Posted: 22 Dec 2015, 01:54

by Ellipse

Hypershpere - you'd need to buy a new bottom inner assembly plate. Everything else would be interchangeable.

Posted: 22 Dec 2015, 01:57

by Hypersphere

Ellipse wrote: Hypershpere - you'd need to buy a new bottom inner assembly plate. Everything else would be interchangeable.

Thanks. I suppose this will become even clearer when the actual sign-up sheet appears.

Posted: 22 Dec 2015, 02:06

by Elrick

Ellipse wrote: There should be a 1-2 month window for sending payment only after the prototypes are confirmed good.

Perfection....... waiting for that 1-2 month window already

.

Posted: 22 Dec 2015, 04:39

by Ellipse

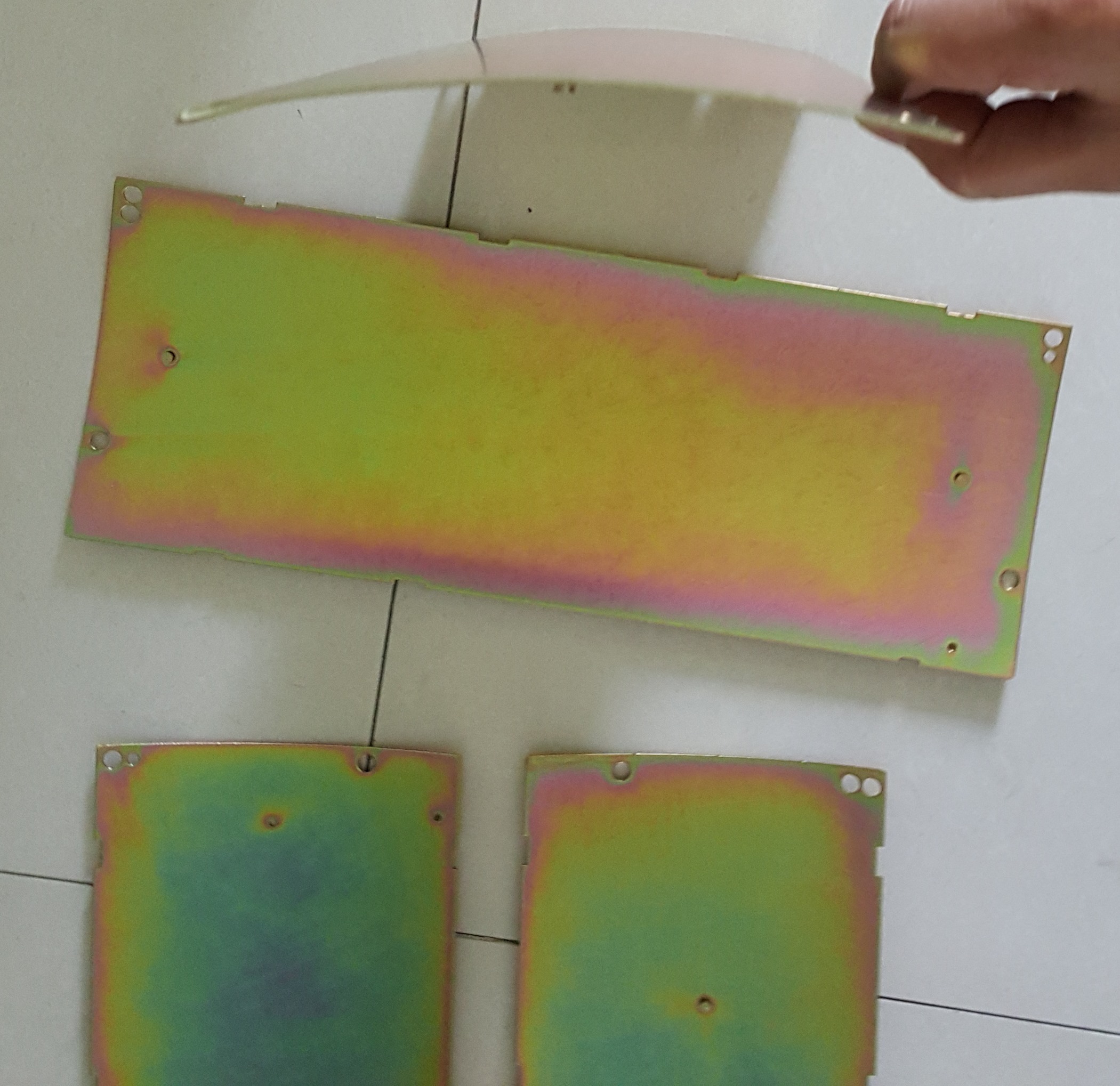

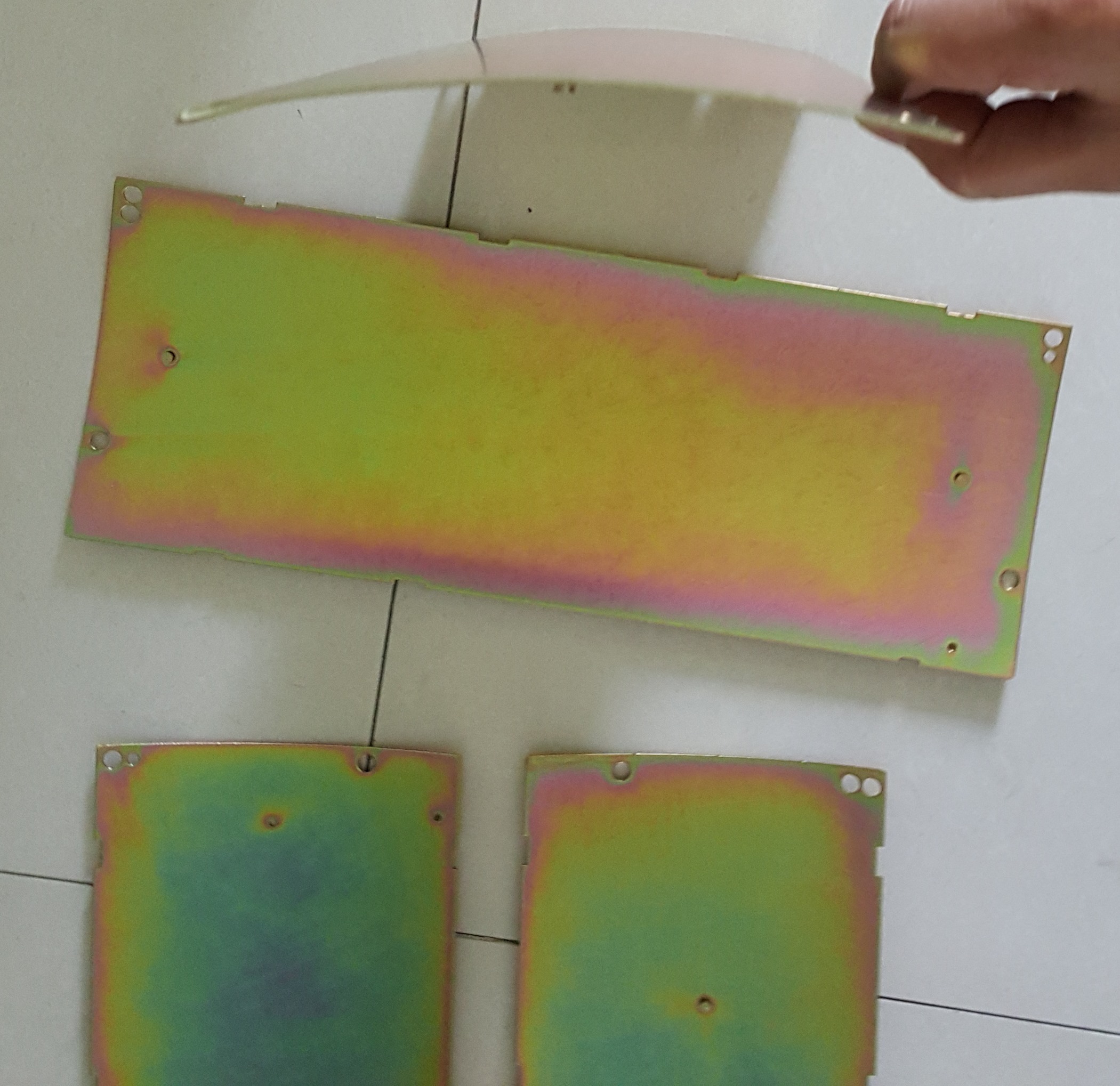

They sent the corrected prototype case photos - I have updated the post from earlier today. The white balance is still inaccurate on all photos, so the paint colors are not representative of what anyone will get.

Posted: 22 Dec 2015, 04:53

by 0100010

I see the updated pics. The holes on the bottom look too small? Where is the raised column and tapped hole for the cable relief? Do the 4 case screw holes on the F62 not go through the tabs on the bottom plate (like they do on the F107)?

For reference :

Posted: 22 Dec 2015, 05:34

by Ellipse

The two holes should be 1/4" - if they are not I will have them make the production ones 1/4". The cable relief cylinder is on the top cover like for your photo - they did not photograph the inside of the top cover. It will be a cylinder with a drilled thread like the original and in the original spot.

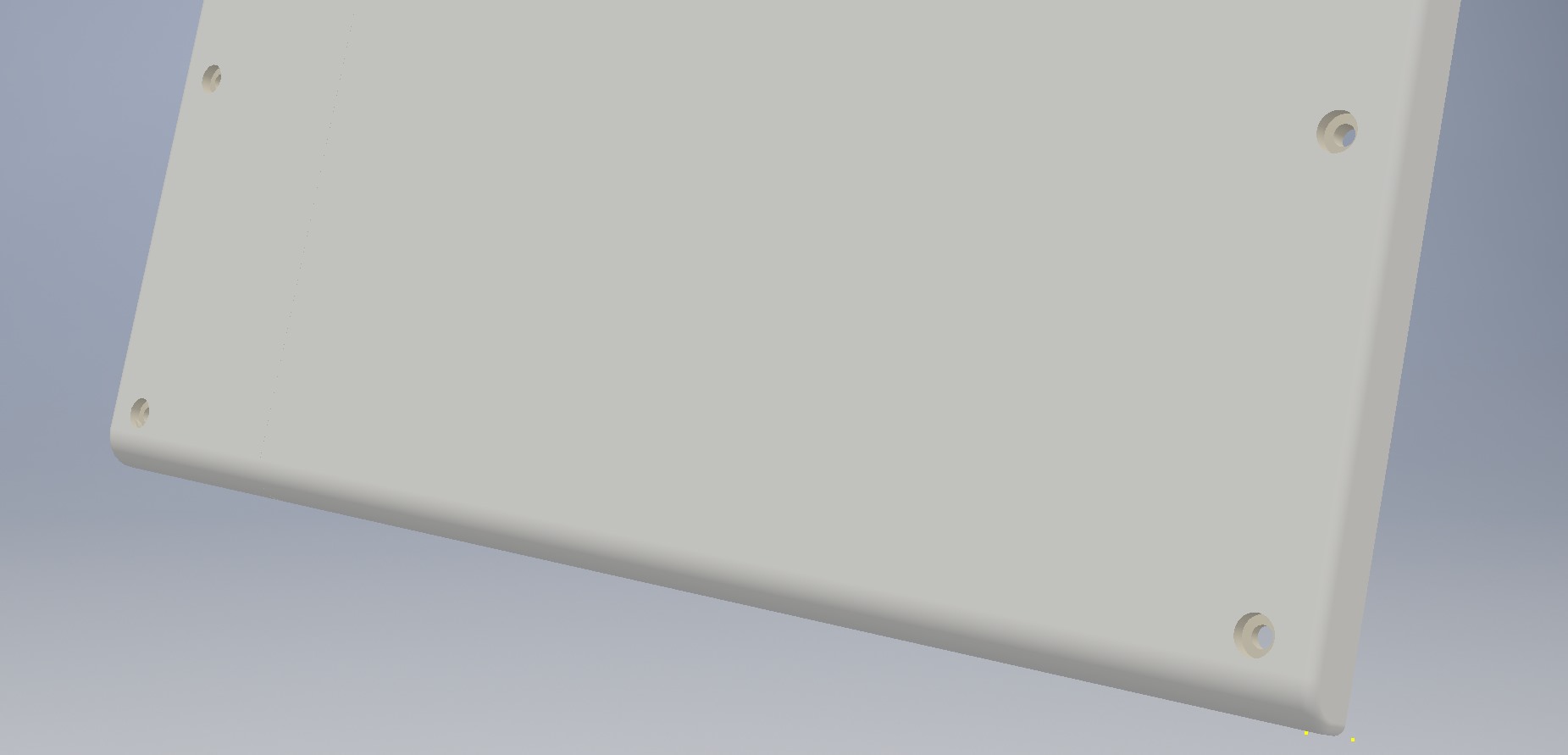

The screws do go inside the bottom case and through the bottom inner assembly like the originals, though I have redesigned the bottom inner assembly to be more like the XT and AT ones as opposed to the 4704s and F122s . I am using different screws, not socket cap screws like the originals but regular computer style 6-32 screws that do not have a large head thickness. Here's a rendering of the back case for reference. The heads of the screws will go completely inside the bottom case like the originals.

- f62 back rendering.jpg (45.53 KiB) Viewed 6547 times

Posted: 22 Dec 2015, 05:36

by Ellipse

And Vizir - judging from the photo that 0100010 posted, it looks like a solenoid and the solenoid driver will fit inside the new F77 keyboards, as they appear to fit inside the pictured F107 with plenty of room to spare.

Re: Brand New F62 Kishsaver / F77 Industrial Model F's made this year

Posted: 22 Dec 2015, 06:54

by Vizir

Great! Good to know.

So many options! First it was deciding between the 62 and the 77. Next came which layout, stock or hhkb. Then came the colors and now we have case design. *cry*

I suck at making these decisions.

Posted: 22 Dec 2015, 11:08

by kekstee

Haha, still not entirely decided either. I guess it will come down to keyset support eventually. Blanks are a bit more versatile already, but even then it seems Unicomp cannot deliver all that is required.

Posted: 22 Dec 2015, 12:29

by Elrick

Vizir wrote: I suck at making these decisions.

You have to start somewhere so this would seem a good time to start.

This what we do all the time (men) hence you get use to making decisions that shall be blessed and sometimes decisions that are regretted.

This one will be a decision made only once in your life because Ellipse won't be making them again.

Posted: 22 Dec 2015, 15:31

by Hypersphere

kekstee wrote: Haha, still not entirely decided either. I guess it will come down to keyset support eventually. Blanks are a bit more versatile already, but even then it seems Unicomp cannot deliver all that is required.

If you are okay with blank black keys, you could dye the keycaps to get the blanks you need.

Posted: 22 Dec 2015, 15:43

by chalks

I'm trying to choose between a F62 in the original case or a F77 in the smaller case.

I changed from a full size board to a TKL to bring the mouse closer to me. The TKL is 14" wide, which I think is the same as the F62 in the original case.

I prefer the F77 layout because it can have separate cursor keys. I have never used a 60% layout and so am not sure about adapting to it. But at, I think, 16.5" wide the F77 in an original case may be too wide for me.

So for me, the choice is between the classic look or a more flexible layout. Is there anything else that I need to consider when choosing between these two?

Is the smaller case for the F77 15.5" wide? Can it be made any narrower, say 15"?

Will prototype smaller cases be made?

If the smaller case is not CNC milled, how is it being made?

I selected the F62 in the interest check form. If I wish to change to the F77 in the smaller case, do I need to submit a new form?

I normally use ISO but I'm tempted to try ANSI. What's involved in changing the layout from ISO to ANSI? Do I just need to put different keys on the board and reprogram the controller or do I need to open the board up and move some stabilisers around too?

kekstee wrote: Haha, still not entirely decided either. I guess it will come down to keyset support eventually. Blanks are a bit more versatile already, but even then it seems Unicomp cannot deliver all that is required.

What are these issues?

Sorry for loads of questions. Given the cost I want to make sure that I make the right choice.

Posted: 22 Dec 2015, 16:19

by 0100010

Ellipse wrote: The two holes should be 1/4" - if they are not I will have them make the production ones 1/4". The cable relief cylinder is on the top cover like for your photo - they did not photograph the inside of the top cover. It will be a cylinder with a drilled thread like the original and in the original spot.

The screws do go inside the bottom case and through the bottom inner assembly like the originals,

though I have redesigned the bottom inner assembly to be more like the XT and AT ones as opposed to the 4704s and F122s. I am using different screws, not socket cap screws like the originals but regular computer style 6-32 screws that do not have a large head thickness. Here's a rendering of the back case for reference. The heads of the screws will go completely inside the bottom case like the originals.

f62 back rendering.jpg

Ah. So the plates are like this :

EDIT : Nevermind. I see the bottom plate pics you posted earlier :

Re: Brand New F62 Kishsaver / F77 Industrial Model F's made this year

Posted: 22 Dec 2015, 19:59

by nfc

Great job!

Just for curiosity... What CAD system are you using?

Posted: 23 Dec 2015, 21:32

by Ellipse

chalks no worries on the questions - both new design cases are about an inch less wide. They cannot be much narrower due to the inner assembly. Yes I hope to make the alternative prototype cases but they will be ready in several weeks at the earliest, but certainly before the GB closes.

I can update your form if you change your mind - no need to resubmit. Feel free to let me know what you decide.

To change from ANSI to ISO you will need to remove all the keys, open up the inner assembly, and move some flippers around. Or you can buy two inner assemblies, one for each layout

I believe the issue with Unicomp was they could not produce black regular-style right shifts any more, so you would need to dye a key black or use the caps lock-1u key combination in that spot.

Posted: 23 Dec 2015, 21:37

by Ellipse

The little parts from McMaster-Carr have arrived! A sampling of screws, foam, bumpers, nuts, washers, etc. More will be ordered based on what's required and what people indicate in their order forms.

All of their bumpers feel very well-made and should be great for this project. I personally prefer the cork-rubber bumpers reminiscent of the original XT keyboard.

- parts.jpg (476.94 KiB) Viewed 6379 times

Posted: 24 Dec 2015, 20:54

by chalks

Ellipse wrote: I can update your form if you change your mind - no need to resubmit. Feel free to let me know what you decide.

Thanks for answering Ellipse. I'll stick with what's on my form for now. I would like to see the prototype smaller case before deciding whether to go with that or not.

Posted: 25 Dec 2015, 00:02

by Ellipse

ok chalks. All I have for now is the prototype case renderings. I am hoping to put those alternative prototypes into production soon.

Does anyone else have feedback on the alternative design cases? Feel free to PM me as well to discuss.

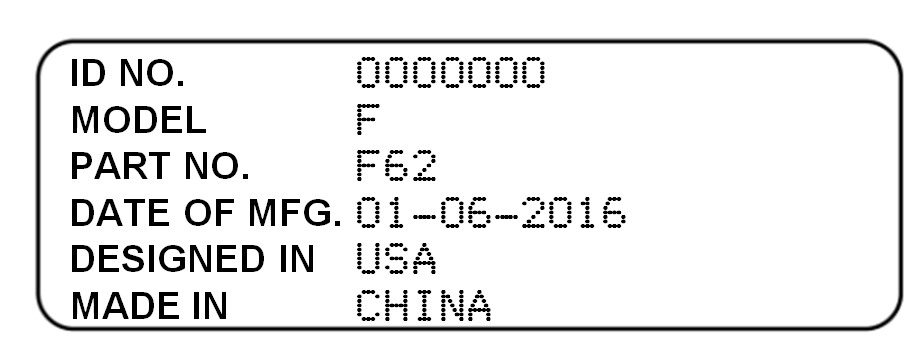

The silver-colored labels have arrived and they look great! Here is the first draft of the label design:

- label test2.jpg (51.17 KiB) Viewed 6260 times

Posted: 25 Dec 2015, 00:08

by XMIT

nfc wrote: Great job!

Just for curiosity... What CAD system are you using?

I'm also curious to know this.

Posted: 25 Dec 2015, 00:42

by Muirium

Be honest:

Designed in USA.

Made in China.

Doesn't everything manufactured there need to have Made in China stamped on it somewhere?

Posted: 25 Dec 2015, 01:07

by chzel

Muirium wrote: Be honest:

Designed in USA.

Made in China.

Doesn't everything manufactured there need to have Made in China stamped on it somewhere?

And funded at least partly by Europeans.

I'd forgo the "Designed in USA" part. I'd prefer a "Designed by IBM" to be honest.

Posted: 25 Dec 2015, 01:10

by scottc

Yeah, I don't know if I like the "key: value" approach for things that just aren't variables. Seems like a bad format to put things in if they're never going to change! If anything, it should be like:

Code: Select all

ID NO. 12345

MODEL F16

FOO BARBAZ123

DESIGNED IN USA

Though maybe this isn't true of original IBM boards. Ah well.

Posted: 25 Dec 2015, 01:27

by Ellipse

Good call Muirium - I added a Made in China part and updated the label.

Scott - I would like the label to be the same format as the original label.

Posted: 25 Dec 2015, 02:33

by codemonkeymike

@scottc no problem assigning strings to constants

Posted: 25 Dec 2015, 15:02

by Spaceman1200

Can't wait for this, been working some OT just to make sure i can get one these bad boys.

Posted: 27 Dec 2015, 02:00

by Ellipse

Hopefully these prototypes ship early next week!

The backend for the store is up and running with products and possible variations. Of course ordering is disabled until everything is ready. A community member is working on the design for the web site, and a few DT/GH members are working on content.

Posted: 27 Dec 2015, 02:27

by Elrick

Ellipse wrote: Hopefully these prototypes ship early next week!

The backend for the store is up and running with products and possible variations. Of course ordering is disabled until everything is ready. A community member is working on the design for the web site, and a few DT/GH members are working on content.

Thought you'll take a Christmas break, never mind the fact I have to work over this period, as all 24/7 shift workers here in Convict Town, but you shouldn't be following our path here.

Thanks for keeping us informed about this venture, appreciate all the effort you've gone through in making this happen.

A Happy New Year is coming up fast.

Posted: 27 Dec 2015, 02:58

by ramnes

Ellipse wrote: ok chalks. All I have for now is the prototype case renderings. I am hoping to put those alternative prototypes into production soon.

Does anyone else have feedback on the alternative design cases? Feel free to PM me as well to discuss.

I really want an alternative case, but sadly the one you posted isn't to my taste.

I never used a 3D software, so I can't really help on this, but I would love a design close to custom 60% like the KMAC mini, Hammer, or other things like this, with sharp edges and thick sides.

(sorry, 3AM Gimp skills)

Of course, I know there are limitations due to plate size and curve, and I'm sorry I can't help more, but I'd love to see other alternative designs.

Re: Brand New F62 Kishsaver / F77 Industrial Model F's made this year

Posted: 27 Dec 2015, 03:15

by Techno Trousers

^ so basically no top case at all? Interesting, but I don't know if that would work, given the finicky electrical needs of the capacitive plate.

Posted: 27 Dec 2015, 04:26

by wcass

Techno Trousers wrote: ^ so basically no top case at all? Interesting, but I don't know if that would work, given the finicky electrical needs of the capacitive plate.

If one keeps to the IBM design rules, the smallest border around the switches that i can figure out would be just under 0.5 inches along the top edge and about 0.3 on one side and bottom edge.